How Autonomous AI Tackles Quality Control Costs

Quality is often viewed as a direct driver of customer satisfaction and operational efficiency in manufacturing. Yet some organizations fail to recognize the hidden costs of quality issues, significantly impacting the bottom line.

Battery inspection using machine vision - fast, reliable, and variable

Averna has developed a procedure for automating battery inspection for one of its customers. The fact that potential errors are extremely varied increases the complexity of the inspection process.

How to Achieve the Full Benefits of a Warehouse Digital Twin

A warehouse digital twin needs more than a highly capable WMS, it also needs a reliable technology to capture all the necessary inventory data, and this is where computer vision plays a pivotal role.

Physical AI: Embracing AI's Moment in Robotics

Manufacturers currently use automation to streamline workflows, enhance efficiency, cut costs, and meet growing consumer demands. Yet they face a myriad of disruptions such as labor shortages, limitations of current technologies, and costly downtimes on production lines.

Multi-axis motion control drives pipe-based robots

Surveying and maintaining underground pipes can be complex and resource intensive. To streamline the process, construction and facility management teams are increasingly turning to robots that can provide inspection as well as repair.

Multi-camera system with AI and seamless traceability leaves no chance for product defects

VIVALDI Digital Solutions GmbH has developed an exemplary, innovative solution for AI quality inspection in real time. In addition to an edge server with an Intel processor, intelligent image processing plays a key role in the so-called SensorBox.

What is the role of cameras in pick and place robots?

Pick and place robots perform repetitive handling tasks with speed and consistency, making them invaluable across industries. These robots depend heavily on the right camera setup. Get insights about the challenges faced by cameras, use cases, and their biggest benefits.

Automate 2025 Product Preview

Automate 2025 takes place May 12th - 15th in Detroit, MI. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Addressing Challenges in Software Solutions for Robots and Physical AI

We leveraged our long heritage and leadership in robotics to create an AI software product that helps our customers overcome the challenges of traditional automation, accelerate set-up and deployment, and achieve greater ROI from their existing automation systems.

Automate 2025 Q&A with DESTACO

There's nothing like seeing our products in action. We will have live demonstrations, giving attendees the chance to see the performance and capabilities of our solutions up close and personal.

Automate 2025 Q&A with igus

We will show how our components can help bring automation machinery to the next level by using our components but also how our robotics department can solve your problems for you with our robotics platform called RBTX.com.

Automate 2025 Q&A with Zimmer Group

We have evolved from a manufacturer of single components to becoming a full-range provider of complex system solutions in the field of robotics. Our portfolio covers the entire automation spectrum - from high-functioning grippers to robot accessories.

Will AI Take My Job in Manufacturing?

While employees have every right to be sceptical about AI, it's important to note that integrating AI into existing workflows is actually in place to enhance productivity and remove the need for time-consuming manual tasks.

Feasibility Studies for Robot Applications: The Key to Successful Project Launch

Before deploying robots, the production process�' suitability for automation must be carefully examined. Especially as robot projects are becoming more complex and efficient implementation is more important than ever, thoughtful planning is essential.

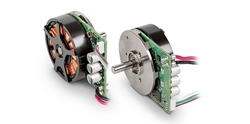

Automate 2025 Q&A with maxon group

If your application requires drive systems, stop by the maxon booth to see the latest in dc brushed, brushless and geared motor technology. We offer standard, semi-custom and fully customized drive solutions and our experts are there to help guide you.

Records 1 to 15 of 1193

Industrial Robotics - Featured Product

igus® - Free heavy-duty plastic bearings sample box

The iglide® heavy-duty sample box provides a selection of five unique iglide bearings, each suitable for use in heavy-duty equipment due to their self-lubricating, dirt-resistant properties. Each bearing material boasts unique benefits and is best suited for different application conditions, though each can withstand surface pressures of at least 11,603 psi at 68°F.