Prepare for the Biggest and Most Comprehensive PACK EXPO Las Vegas

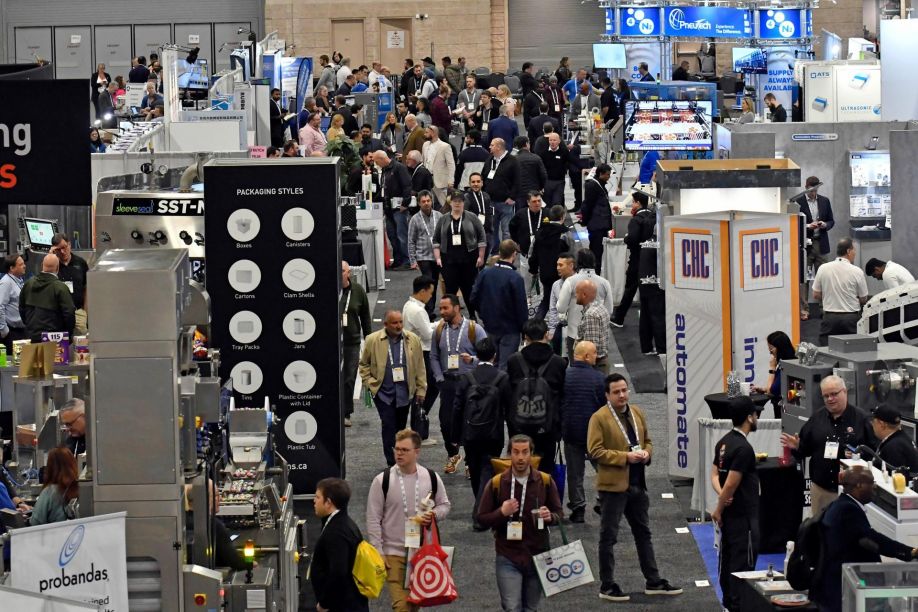

PACK EXPO Las Vegas is this year's largest gathering of packaging and processing professionals, offering attendees unique opportunities to uncover key technology solutions and make the connections that drive businesses forward.

PACK EXPO 2025 Product Preview

PACK EXPO 2025 takes place September 29th - October 1st in Las Vegas, Nevada. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Talking PACK EXPO Las Vegas with CMES Robotics

We will be in the PAC Machinery booth (W-2344). Adding a robot that can perceive virtually any CPG item gives companies the option for a pick-to-bag solution that is going to be truly unique and special on the floor.

Talking PACK EXPO Las Vegas with igus

Anyone at the show who visits our booth will be able to find something relevant to their own operations that can solve a key problem and offer improved performance, lower costs, and greater sustainability.

PACK EXPO Southeast 2025: The Future of Packaging & Processing Arrives in Atlanta

This brand-new regional show promises to connect industry leaders, innovators and decision-makers while showcasing cutting-edge technologies that will shape the future of manufacturing across more than 40 vertical markets.

Get Ready for the Largest and Most Comprehensive PACK EXPO International Ever

With over 1.3 million square feet of exhibition space, the show will showcase innovations from nearly 2,700 exhibitors serving more than 40 industries, making it the premier destination for anyone in the packaging and processing world.

PACK EXPO 2024 Product Preview

PACK EXPO International 2024 takes place November 3rd - 6th in Chicago, Illinois. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

PACK EXPO 2023 Product Preview

PACK EXPO 2023 takes place September 11th - 13th in Las Vegas, Nevada. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Talking PACK Expo with Brenton Engineering

Las Vegas is a place tailor-made for big reveals, which is why it's the perfect location to launch our new XCP Series continuous motion case packer. The XCP is designed for that mid-level customer looking to package between 35-70 cases per minute.

Omron to showcase an interactive experience that combines pick-and-place, materials transport and end-of-line palletizing at PACK EXPO 2022

Optimizing operations is essential in the packaging industry from processing to logistics and warehousing. At booth S-3832 at PACK EXPO, Omron's interactive experience showcases a complete, flexible and fully automated solution that empowers people through automation.

PACK EXPO 2022 Product Preview

PACK EXPO 2022 takes place October 23rd - 26th in Chicago, Illinois. The Exhibit hall floor will be loaded with new products and services. Here is a preview of some things to look forward to at this years event.

Robotic Washdown in Food-Handling Environments

Heavy washdown and harsh chemical solutions used to clean robots in FDA and USDA sanitary environments for food processing can impact the robot finish, as well as leave condensation on robotic machinery that could potentially reach food products

being handled.

How-To Guide on Mastering PACK EXPO Connects

With so many activities and over 2,600 scheduled demos taking place at PACK EXPO Connects, here is every preparation tool attendees need to ensure a successful event.

Detecting New Solutions: How Intelligent Sensors Can Support Industry 4.0

Innovation Stage Q&A with SICK Inc. - To explore the impact of I4.0 and sensors in automated pharmaceutical manufacturing, we spoke with Ron Stuver, director of business consulting at SICK, Inc. (Booth LS-6419), a leading provider of manufacturing sensors.

PACK EXPO 2019 - Harmonic Drive

Harmonic Drive is well-known for our zero-backlash strain wave gear products. Many machine designers and builders don't realize that we also manufacture Planetary gears. Booth #LS6068

Records 1 to 15 of 59

Featured Product

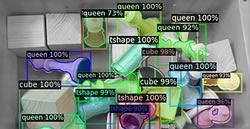

Palladyne IQ - Unlocking new frontiers for robotic performance.

Palladyne IQ is a closed-loop autonomy software that uses artificial intelligence (AI) and machine learning (ML) technologies to provide human-like reasoning capabilities for industrial robots and collaborative robots (cobots). By enabling robots to perceive variations or changes in the real-world environment and adapt to them dynamically, Palladyne IQ helps make robots smarter today and ready to handle jobs that have historically been too complex to automate.

Robotics and Automation - Featured Company

Oriental Motor Corp. USA

Since our founding in Japan in 1885, Oriental Motor globally has been providing the optimal motion systems as part of our total service, to meet the widest market demands. We manufacture and sell AC Motors, Stepper and Servo Motors, Linear and Rotary actuators, Network Solutions, Accessories and Thermal Management solutions. Oriental Motor's sales and service network is international, with offices throughout North America, Europe and Asia.