How We Gave Fawn Memory: Building Persistent, Cross-Platform Memories for Emotional Intelligence in AI

The future of emotional AI doesn't just require intelligence-it requires memory that works the way human memory does, with all its contextual awareness, emotional significance, and imperfect but meaningful recall.

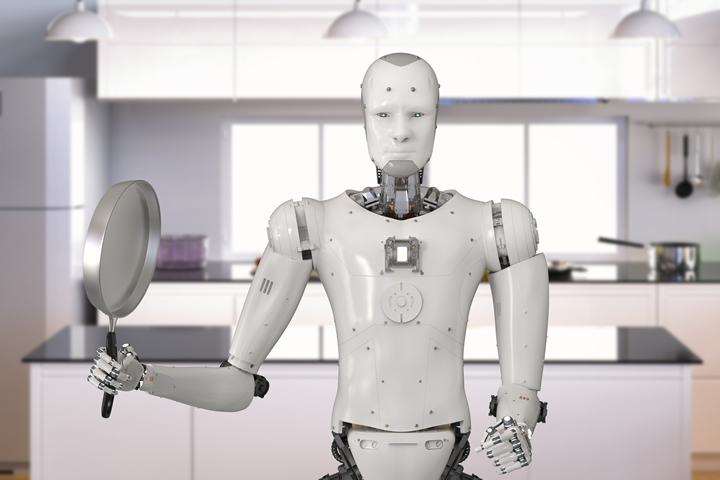

Chef Robotics Announces $43M Series A Round Led by Avataar Ventures to Scale the Deployment of AI-Enabled Robotics

Now at over 44M servings produced and counting through robot deployments at leading brands such as Amy's Kitchen, Sunbasket, Chef Bombay, and Cafe Spice, Chef has procured more meals than all other existing food robotics startups combined.

New Autonomous World Speed Record Set With Indy Autonomous Challenge Maserati MC20

AI-Driver of Politecnico di Milano Sets New Autonomous Speed Record with Indy Autonomous Challenge Maserati MC20 Coupe, reaching 197.7 mph (318 km/h), during the 1000 Miglia Experience Florida, at Kennedy Space Center.

Decrease Downtime: Ergonomic Process for Healthier, More Productive Workplace

Preventing worker discomfort and addressing early signs of injury are proven to save companies time and money, all while improving worker satisfaction and reducing turnover.

Reliable Robotics Demonstrates Flexibility of Autonomous Flight System in an Operational Mission for the U.S. Air Force

"This successful demo underscored two important mission enablers--the ability to deploy Reliable's control station wherever the Air Force needs and convert existing aircraft using our aircraft-agnostic autonomous flight system." -Reliable's Dr. David O'Brien

One person can supervise 'swarm' of 100 unmanned autonomous vehicles, OSU research shows

The findings represent a big step toward efficiently and economically using swarms in a range of roles from wildland firefighting to package delivery to disaster response in urban environments.

Which Product Transfer is Best - Pros and Cons of 6 Transfer Methods

The transfer method can vary widely depending on the product and process being performed. We'll review the five main transfer options available, discuss their pros and cons, and show which application they are best suited for.

Women in Engineering: Embracing Diversity & Encouraging Passion to Optimize Outcomes

The topic of women in engineering is of paramount importance today because diversifying the engineering field ensures a broader range of perspectives, fostering innovation and better solutions to complex challenges.

Study: Robots and AI Offer Significant Carbon Emissions Reductions by Operating Centuries Old Industries Better

By incorporating better use of data into some of the world's most carbon-dependent industries, the study found the equivalent of up to 18% of U.S. emissions could be eliminated by better operation.

Exploring the Future of Machined Exoskeleton Technology in Medical Rehabilitation

The future of aluminum exoskeleton robot technology holds great promise in the medical rehabilitation industry.

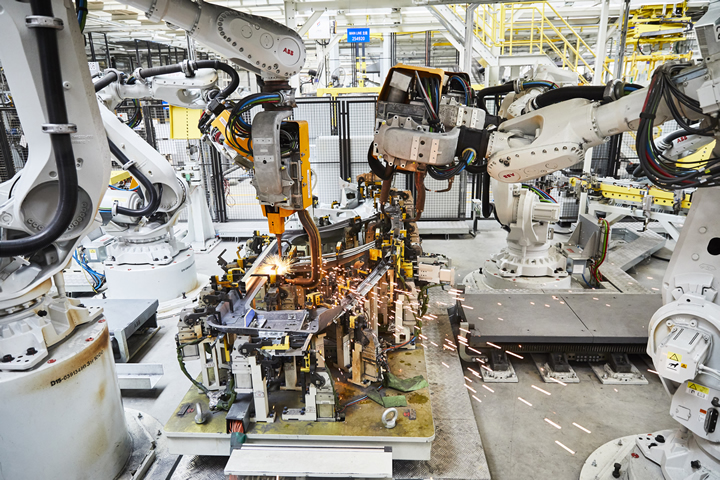

Smart robotic automation solutions from ABB to support sustainability targets for Volvo Cars

ABB's new family of energy efficient large robots and OmniCoreTM controllers will help Volvo Cars deliver energy savings of up to 20 percent and achieve its ambitious sustainability targets.

Enhancing Production Efficiency Through Intelligent Transfer Systems

A smooth production process is critical for a company's success. The constantly growing demands of the market and increasing cost pressure require innovative solutions to optimize production. This is where transfer systems come into play.

Robots are taking human roles - and SMEs need to be ready

A mantra often heard within the manufacturing and logistics industries is that robots are not taking the jobs of humans. And, in many ways, this is true. Today, automation is even a necessary solution to plug a shortage of human labour.

Terabase Energy Completes First Commercial Deployment of Terafab™ Solar Construction Automation System

The benefits demonstrated by this project underscore the transformative potential of automation in advancing solar construction practices, enabling us to accelerate and de-risk our project pipeline

AGV and AMR Are Becoming More Complex

To enable the industry to keep pace with trends through quick and cost-efficient development, Markus Fenn and Prof. Dr. Stefan May developed Eduard, a teaching and prototyping platform that can be used to map current trends.

Records 1 to 15 of 716

Featured Product

High Performance Servo Drives for localized and distributed control applications from Servo2Go.com

Engineered to drive brushless and brush servomotors in torque, velocity or position mode, Servo2Go.com offers a broad selection of servo drives in a wide range of input voltages and output power levels.

.jpg)