Robotics Providers: Challenges and Opportunities in a Dynamic Industrial Equipment Market

In this blog post, we'll explore some of the key trends and challenges facing robotics providers today, and offer insights into how they can navigate this dynamic landscape to build successful businesses.

Unlock the Secrets to Success in the Robotics Industry

The robotics industry is constantly evolving with new advancements in technology and increased demand for robots. Sounds like a great market opportunity, but designing robots comes with its own set of challenges.

White Paper from Onshape: The Engineering Leader's Guide to Data Management

In this introductory guide, learn the critical role that data management plays at every stage of the product design and manufacturing process, and how cloud-native tools can help prevent data bottlenecks altogether.

COBOTS VS COVID: Today's Manufacturing Reality and Tomorrow's New Normal

THIS WHITE PAPER discusses how manufacturers in many industries are leveraging collaborative robots (cobots) to create safe zones for workers returning to production lines.

COMPUTER VISION AND ROBOTICS EXPAND INDUSTRIAL CAPABILITIES

How can industrial robots gain new abilities that can increase their operational value while remaining safe and secure in a factory collaborating with humans?

SICK is taking safety to the next level with collaborative robot systems

There is an increasing demand for collaborative robots that can work autonomously and adapt to changing production conditions. This requires reliable sensors that detect human presence and can overcome future challenges with the development of collaborative technologies.

Conventional vs. Robotic Palletizing

Rather than getting immersed in ambiguous statistics and marketing buzzwords like flexible or fixed automation, this paper looks at the specific applications that favor each technology to chart the future of palletizing automation.

Best Practices for Real-Time Machine Automation Performance in IoT & Industry 4.0

Learn how IntervalZeros RTOS platform transformed machine automation in Japan

The Less is More Approach to Robotic Cable Management

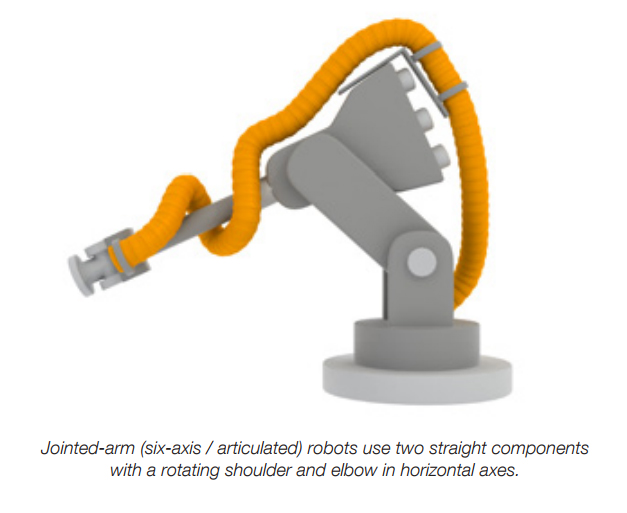

Current systems try to keep the cables on a six-axis robot static while everything operating around them is dynamic. Instead, consider a six-axis robot as three separate sections: the sixth to third axis; the third to second axis; and the second to first axis.

Records 1 to 9 of 9

Featured Product

Midwest Motion Products is a leading provider of robust and reliable Motion Control Products.

MMP specializes in supplying high-quality Brushed & Brushless DC Motors & Gearmotors for Robotics and Automation Equipment with a wide range of motor windings and gear ratios. With an impressive track record of more than 8,000 released DC Gearmotors designs and over 2,000,000 individual part numbers, we are renowned for our ability to handle large-scale orders. Due to our huge on-hand inventory, we are also well known for lightning-fast delivery of our standard products. We take pride in our dedicated customer service and our team of knowledgeable sales and engineering experts who are ready to assist you with custom design solutions tailored to your specific application. Additionally, we also offer a wide range of complimentary products, such as DC Motor Controls, DC Linear Actuators, AC-DC power Supplies, and DC Servo Amplifiers and others.

Robotics and Automation - Featured Company

Freudenberg Sealing Technologies

Freudenberg Sealing Technologies is a proven supplier for demanding products and applications, and a development and service partner to customers in the automotive industries and in general industries. We apply 175 years of engineering and materials expertise. Then and now - we are focused on serving our customers' requirements and needs. Starting with the development of the Simmerring® radial shaft seal in 1929, Freudenberg Sealing Technologies has continuously expanded its industrial seals and component portfolio to include a range of technology solutions that address critical issues like performance, power, friction, emissions and material compatibility.