2025 Top Article - Redefining industries with robotics and AI

2025 Top Article - Purpose-Built, Specialized Robots are the Future

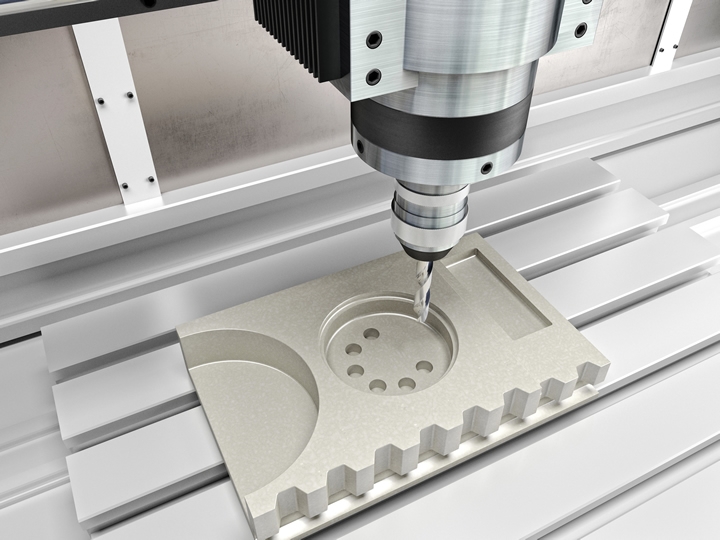

2025 Top Article - The Future of Machining: Key Trends and Innovations

2025 Top Article - The Ultimate Guide to Depth Perception and 3D Imaging Technologies

StackTrax - The Industry's First Off-The-Shelf Dual Axis RTU

The Hiring Freeze Came First. The Robots Came After.

ReBeLMove Pro: modular robot platform for logistics, assembly and handling

CASE STUDY STT SYSTEMS and STEMMER IMAGING: AUTOMOTIVE BOLT INSPECTION SYSTEM WITH GOCATOR SMART 3D LASER PROFILERS

How U.S. Manufacturing VPs Can Close the Execution Gap — The New Playbook for Operational Excellence

The Right 3D Vision Scanner for Robotic Programming: Laser Profilers vs Structured Light Scanners in Industrial Automation

ATEC2025·Real-World Extreme Challenge Concludes with Zhejiang University Team Claiming $150,000 Prize for Breakthrough in Fully Autonomous Robotics

BTM INDUSTRIAL IS HOSTING AN ONLINE SALE OF INDUSTRIAL ROBOTS ON DECEMBER 17-18, 2025

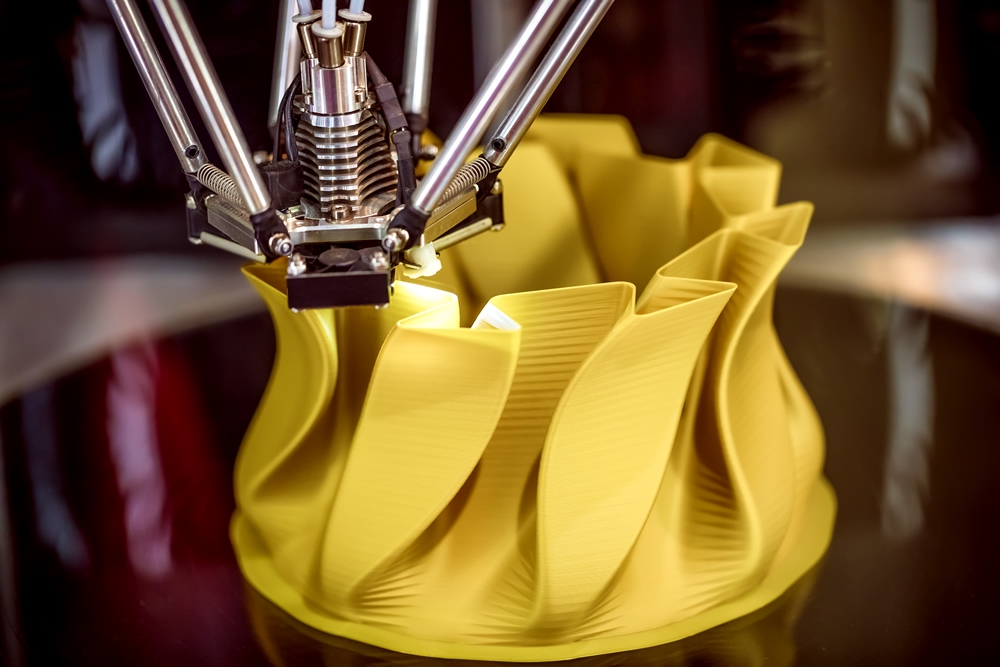

What are the motion control requirements for additive manufacturing machines?

What is Agentic AI and is it here to stay?

Automation Solutions Mergers & Acquisitions Update

Records 16 to 30 of 3743

First | Previous | Next | Last

Featured Product

MVTec MERLIC 5.8

Robotics and Automation - Featured Company