Why Robots Are About to Change Everything AND WHY NOW

The convergence of AI breakthroughs and robotics is creating a moment for which the field has been waiting decades.

Aerospace's Automation Breakthrough: How Robotics and AI Orchestration Are Rewriting the Supply Chain

For aerospace, the next leap will come from integrating physical automation with AI systems capable of coordinating the flow of information across complex, multi-vendor, secure environments that protect confidential information all while transforming efficiency..

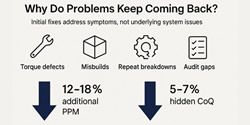

KPI Growth has an enemy called "Recurrence" - Fight it with Standard Work to Sustain the Growth.

Continuous Improvement is often misunderstood as an engine for solving more problems. In reality, the defining capability of a mature operation is ensuring the same problems never return.

Fully Autonomous Deliveries inside Multi-floor Buildings without Elevator APIs

Once a robot can move between floors without any changes to existing building infrastructure, operators get immediate ROI by freeing staff from repetitive delivery work while improving speed and convenience for residents and guests.

Stefa Mini Solutions for Next-Generation Robotic Applications

The Stefa Mini, Cassette and Nano Seals all have smaller cross sections than comparable seals in the market today. This matters because a smaller seal allows for smaller glands (the area the seal slips into on the equipment) and smaller glands mean overall smaller equipment.

How to Build a Digital Foundation for Your Robotics and Automation Strategy

A strong digital foundation brings everything together, allowing automation initiatives to scale, adapt and perform as intended. Without it, automation efforts often stall before they reach their full potential.

Powering Robotics: How Networks Enable the Era of "Physical LLMs"

Physical AI describes intelligent systems that can sense, interpret, and act in real environments. Think of self-driving cars navigating busy streets, robotic arms assembling machinery with precision, or smart grids adapting in real time to energy demands.

Facility Maintenance: Lavo Bot AI and NVIDIA Bring Autonomy to Exterior Surface Cleaning

Equipped with advanced mapping, multi-sensor vision and zone-based safety, the system navigates real-job sites with confidence—handling up to 6,000 sq ft/hour and supporting pressure-wash rigs up to 12 GPM and 4,500 PSI.

The ifm Obstacle Detection System (ODS)

The ifm Obstacle Detection System (ODS) optimizes the robot's overall performance by treating obstacle detection as a holistic system rather than just a camera. It provides reliable obstacle detection to protect people, equipment, and mobile robots.

Physical AI and Autonomy in the Construction Industry

Bedrock is taking advantage of the dramatic accessibility of GPUs and frameworks for scaled data access and training, combining it with our unique understanding of how to build and create autonomy solutions quickly and efficiently.

International robotic safety conference 2025: Key takeaways shaping the future of safe automation

The International Robotic Safety Conference highlighted how rapidly the safety environment is evolving, driven by new standards that reflect innovative robotics technologies and tightening global regulations.

How to Overcome Cobot Design Challenges

Although collaborative robots have become widely available and used in numerous industries, the professionals who design them frequently encounter and must overcome various challenges in cobot design. How should designers address them?

Robot-Driven Manufacturing Enables "Lights-Out" Production

The required solution would need to provide seamless connectivity and communication with the RoboDrill machines, as well as additional factory machinery throughout the company targeted for robotic automation moving forward.

Robotecki Redefines Robotics Precision Cutting and Drilling Applications with RoboDK

With their application, the team at Robotecki not only reduced labor-dependency for these key tasks, they improved the quality of production and throughput.

The Future of Autonomous and Wireless Charging

The real driver of change has been the need to reduce manual intervention and lower operational costs. When a robot can charge itself safely and autonomously, maintenance downtime drops dramatically, and so does total cost of ownership.

Records 1 to 15 of 3746

Featured Product

Model TR1 Tru-Trac

The Model TR1 Tru-Trac® linear measurement solution is a versatile option for tracking velocity, position, or distance over a wide variety of surfaces. An integrated encoder, measuring wheel, and spring-loaded torsion arm in one, compact unit, the Model TR1 is easy to install. The spring-loaded torsion arm offers adjustable torsion load, allowing the Model TR1 to be mounted in almost any orientation - even upside-down. The threaded shaft on the pivot axis is field reversible, providing mounting access from either side. With operating speeds up to 3000 feet per minute, a wide variety of configuration options - including multiple wheel material options - and a housing made from a durable, conductive composite material that minimizes static buildup, the Model TR1 Tru-Trac® is the ideal solution for countless applications.

Robotics and Automation - Featured Company

Zimmer Group US, Inc.

Are you interested in premium products in the fields of mechanical and plant engineering? Do you want to learn more about our solutions in the fields of automation, damping, linear, processing, tooling, and machine tooling technology?

.jpg)