How Autonomous Mobile Robots are Transforming Material Handling for Automotive Tier Suppliers

New MiR Fleet Enterprise Software Raises the Bar in Scalability and Cybersecurity for Autonomous Mobile Robots

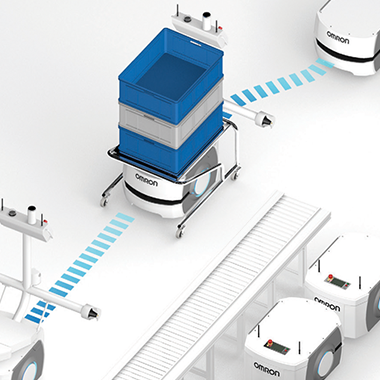

Robots speeding up material handling

The Robot Driven Logistics Industry

Solving the logistics labor puzzle: Choreographing a Tango of Robots and Human Labor in Warehouse Operations

Sneaker and Sportswear Retailer's New Mezzanine and Ground Floor Feature ResinDek Robotic Flooring

ABB unveils its innovative mobile robot with Visual SLAM AI-technology and AMR Studio® Suite

How to Handle Post-Holiday Returns with Warehouse Automation

Introducing Titan, Amazon's new mobile robot that can lift up to 2,500 pounds

Preparing Your Facility for Mobile Robots: Key Considerations for Seamless Integration

Important Trends Impacting the AMR Space

Transforming Manufacturing Processes with AMRs: Boosting Efficiency and Adaptability

Geek+ drives automation of advanced BMW-producing plant in China

Solving Manufacturing Challenges with Autonomous Mobile Robots

AI-powered Perception Engine for Mobile Robots

Records 31 to 45 of 99

First | Previous | Next | Last

Featured Product

NVIDIA RTX PRO BLACKWELL DESKTOP GPUs

Robotics and Automation - Featured Company

.jpg)

.jpg)

_mp4_00_00_37_23_Still004.jpg)