HoloBuilder Announces Partnership with Boston Dynamics

Controlled by HoloBuilder's SpotWalk app, the Boston Dynamics' Spot robot can walk job sites autonomously, capturing 360° images that record the progress of a construction project over time.

Robotics Is Paving New Ground In Construction

With robots available to fulfill most of the mundane jobs in construction, human workers will now be able to concentrate on more skill-oriented tasks.

Construction Robotics Market to Reach $226 Million Worldwide by 2025, According to Tractica

More than 7,000 Robot Assistants, Infrastructure Robots, Structure Robots, and Finishing Robots Will Be Deployed for Construction Between 2018 and 2025

How Robotics and Automation Are Changing the Construction Industry

Ready or not, advanced robotics, AI and automated hardware are all making their way into the construction industry. As these technologies are adopted on a grand scale, we'll start to see many archaic processes upgraded - not just to be more modern, but also more efficient...

Global Construction Robotics Market to Hit $420 Million by 2025

A recent report from QY Research looked at the global construction robots sales market and forecasted that the market would hit $420 million by 2025.

This Robot Tractor is ready to disrupt construction

Matt Simon for Wired: Give it coordinates, tell it what size the hole should be, hit enter, and it tears off and digs the thing with impressive accuracy.

Bricklaying Robots And Exoskeletons Are the Future of the Construction Industry

David Silverberg for Motherboard: The global construction space isn't known for ushering new tech into their workforce, but a painful labour shortage, calls for increased worker safety and more low-cost housing, and the need to catch up to other tech-savvy sectors is giving upstarts in robotics and exoskeletons their big moment.

Fastbrick signs a deal with Caterpillar to develop bricklaying robots

Jessica Sier for The Sydney Morning Herald: Fastbrick is building a commercial version of its robot bricklaying machine, Hadrian X, which will cost about $2 million when it goes into full production in 2019.

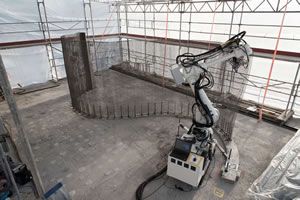

ETH zurich builds DFAB HOUSE using robots and 3D printers

DesignBoom.com: Built using a two-meter high construction robot, the machine works by moving autonomously on caterpillar tracks.

Robotic Construction Platform Creates Large Buildings on Demand

Evan Ackerman for IEEE Spectrum: Construction seems like an industry that, were I still living in Silicon Valley, I would be tempted to call "ripe for disruption." Researchers at the MIT Media Lab agree, pointing out in a paper just published in Science Robotics that construction "relies on traditional fabrication technologies that are dangerous, slow, and energy-intensive." Hey, sounds like a job for some robots, right?

Fastbrick Robotics' bricklaying machine builds investor interest

Tim Boreham for The Australian: According to Fastbrick Robotics chief Mike Pivac, the art of bricklaying hasn’t changed much in the past 5000 years. For brickies’ labourers in particular, it remains an unsafe and back-breaking game of messy mortar-mixing and lugging hods at height or over uneven surfaces.

Backed with seed funding from the publicly listed Brickworks, Mr Pivac and his cousin Mark have devised a robotic bricklaying machine to eliminate the drudge work. About the size of a garbage truck, the prototype Hadrian 105 unit can erect an average house in one to two days, within an accuracy of half a millimetre. That’s far more accurate than the brickies’ time-honoured string and spirit level method.

Led by Cygnet Capital, the Pivacs have been on an investor roadshow ahead of a $3 million raising and reverse IPO, via the shell of former winery owner DMY Capital. Interest has been enormous, with inquiries from as far afield as Saudi Arabia and Russia. “We had 500,000 hits on our website in just over five days,’’ Mr Pivac says. “We have had interest from 35 countries, including some outstanding big organisations.’’ Cygnet Capital director of corporate finance Darien Jagger says no other IPO has attracted as much interest. “We have fielded thousands of emails from all sorts of parties.’’ The Hadrian unit has already demonstrated end-to-end construction, without the need for human intervention.

The innovation lies not with the robotic arms, but the laser-guided system that allows the bricks to be placed accurately. “If you put this machine on a rocking boat it would lay a house on the shore correctly to an inch or two,’’ Mr Pivac said. Cont'd...

Records 31 to 41 of 41

Featured Product

Zimmer Group - THE PREMIUM GRIPPER NOW WITH IO-LINK

IO-Link is the first standardized IO technology worldwide for communication from the control system to the lowest level of automation.

Robotics and Automation - Featured Company

ResinDek / Cornerstone Specialty Wood Products

As the manufacturer of ResinDek® panels, we have been at the forefront of testing and innovating flooring panels for the Material Handling Industry since 1994. In 2007, we began providing ResinDek panels for automated warehouse distribution robots. Much of our initial research and development occurred with Automated Guided Vehicles. In the last decade, we have provided a variety of ResinDek engineered flooring products to numerous Automated Guided Vehicles (AGV) and Autonomous Mobile Robot (AMR) manufacturers for their testing labs. As a result, millions of square feet of ResinDek panels are in service worldwide with robotic traffic in distribution centers, warehouses, microfulfillment centers, and retail environments.