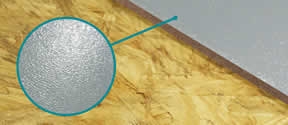

Upgrade Your Mezzanine Flooring While Avoiding Timely and Costly Replacement

Mezzanine floors are important in many facilities. They provide extra space for storage or work without taking up more ground space. However, they often face heavy use from equipment and people. Over time, this can cause the floor to wear down.

ABB introduces most compact, AI-powered AMR for payloads up to 1500 kg

AI-driven Visual SLAM and integrated load sensing enable stable and autonomous navigation, including in challenging conditions. AMR Studio 4.0 version simplifies deployment with no-code programming and real-time fleet management

Robot-Based Shelf Monitoring Cameras for Retail Operation Efficiency

Robot-based shelf monitoring systems integrate camera systems with autonomous robotics. It helps ensure seamless inventory tracking, planogram compliance, and shelf organization. Discover how these camera-based systems work and their must-have imaging features.

DEEP Robotics' Wheel-legged Robot Helps Solve the "Three Highs" Challenge in UHV Substations

Combining the speed of wheeled robots with the agility of legged ones, it stands as the world's first industry-grade wheel-legged robot specifically engineered for complex terrains and hazardous environments.

Hybrid AMRs are a Game-Changer

They can operate seamlessly in unstructured environments and adapt to changing floor conditions. At particular points where highest precision is required, we revert to a QR code location.

Joint actuators: The fundamental component for humanoid robots' power and dexterity

Although there are structural similarities between humanoid robot joints and collaborative robot joints, there are still many differentiated requirements that pose higher performance demands.

Hexagon launches AEON, a humanoid built for industry

Hexagon leverages industry-leading expertise in measurement technologies, AI and autonomous systems to introduce an advanced humanoid robot to accelerate next-generation autonomy.

NEURA Robotics and NVIDIA Collaborate to Advance the Future of Physical AI in Germany

Much like an app store for robotic intelligence, the Neuraverse allows robots to share and continuously evolve their skills: from welding and assembly to household tasks like ironing.

What if the Most Dangerous Jobs Could Run Themselves?

Robots exist to handle specific dangerous tasks - such as diffusing explosive devices or inspecting tall or remote structures. However, many researchers and other concerned parties are running trials and improving concepts in labs to create more broadly applicable machines.

When Trust in Robotics Comes Down to the Internet Connection

We've reached a point where once intractable challenges in the industrial space are being increasingly solved with robotics. Consider these three examples where industrial robotics is playing an increased role in our lives.

The Future of Underwater Robotics

Imagine a robot that can manage aquaculture projects, repair oil pipelines, and scan the seabed - all without risking human life. Nauticus Robotics' flagship robot, Aquanaut, meets these challenges while running solely on electric power.

Aerones Secures $62M in Oversubscribed Financing Round

Funding will be used to expand globally, boost R&D in AI and robotics, scale manufacturing, and enhance predictive maintenance for the wind industry.

Multi-axis motion control drives pipe-based robots

Surveying and maintaining underground pipes can be complex and resource intensive. To streamline the process, construction and facility management teams are increasingly turning to robots that can provide inspection as well as repair.

TeknTrash Robotics and Sharp Group Launch Groundbreaking Humanoid Robot Pilot for Smarter Recycling

ALPHA is trained using real-time motion data collected from recycling operatives via VR headsets and the data is sent in real time to cloud servers. The data is then processed through IsaacLab and deployed to NVIDIA's GR00T framework for real-time inference.

DEEP Robotics Empowers Intelligent Upgrades Across Industrial Scenarios

Combining both wheeled and legged mobility capabilities, it is designed for demanding operational scenarios, driving intelligent upgrades across various applications including industrial inspection and emergency rescue operations.

Records 1 to 15 of 1427

Mobile Robots - Featured Product

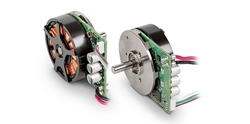

ElectroCraft's Motion Control for Mobile Robots

ElectroCraft is showcasing its award-winning mobile robot technology including their powerful and compact wheel drives, high-torque-density brushless DC motors, precision linear actuators as well as servo motor drive technology at a variety of conferences and tradeshows including the Boston Robotics Summit. Robotics Summit is the premier symposium for the sharing of ideas, technology, and market developments for robotic technologies across industries. Beyond a showcase and pitch of product, ElectroCraft is eager to participate in the collaborative discussion of challenges and opportunities that will shape the near and long-term robotic marketplace.

.jpg)