Reliable Robotics Demonstrates Flexibility of Autonomous Flight System in an Operational Mission for the U.S. Air Force

"This successful demo underscored two important mission enablers--the ability to deploy Reliable's control station wherever the Air Force needs and convert existing aircraft using our aircraft-agnostic autonomous flight system." -Reliable's Dr. David O'Brien

One person can supervise 'swarm' of 100 unmanned autonomous vehicles, OSU research shows

The findings represent a big step toward efficiently and economically using swarms in a range of roles from wildland firefighting to package delivery to disaster response in urban environments.

Which Product Transfer is Best - Pros and Cons of 6 Transfer Methods

The transfer method can vary widely depending on the product and process being performed. We'll review the five main transfer options available, discuss their pros and cons, and show which application they are best suited for.

Women in Engineering: Embracing Diversity & Encouraging Passion to Optimize Outcomes

The topic of women in engineering is of paramount importance today because diversifying the engineering field ensures a broader range of perspectives, fostering innovation and better solutions to complex challenges.

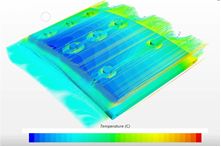

Study: Robots and AI Offer Significant Carbon Emissions Reductions by Operating Centuries Old Industries Better

By incorporating better use of data into some of the world's most carbon-dependent industries, the study found the equivalent of up to 18% of U.S. emissions could be eliminated by better operation.

Exploring the Future of Machined Exoskeleton Technology in Medical Rehabilitation

The future of aluminum exoskeleton robot technology holds great promise in the medical rehabilitation industry.

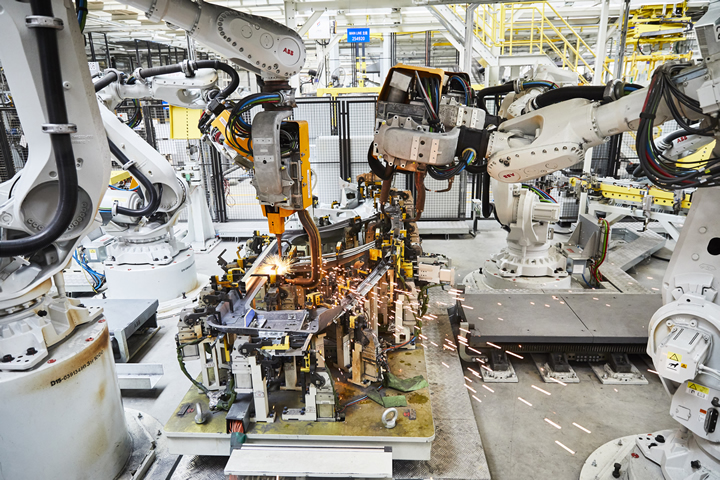

Smart robotic automation solutions from ABB to support sustainability targets for Volvo Cars

ABB's new family of energy efficient large robots and OmniCoreTM controllers will help Volvo Cars deliver energy savings of up to 20 percent and achieve its ambitious sustainability targets.

Enhancing Production Efficiency Through Intelligent Transfer Systems

A smooth production process is critical for a company's success. The constantly growing demands of the market and increasing cost pressure require innovative solutions to optimize production. This is where transfer systems come into play.

Robots are taking human roles - and SMEs need to be ready

A mantra often heard within the manufacturing and logistics industries is that robots are not taking the jobs of humans. And, in many ways, this is true. Today, automation is even a necessary solution to plug a shortage of human labour.

Terabase Energy Completes First Commercial Deployment of Terafab™ Solar Construction Automation System

The benefits demonstrated by this project underscore the transformative potential of automation in advancing solar construction practices, enabling us to accelerate and de-risk our project pipeline

AGV and AMR Are Becoming More Complex

To enable the industry to keep pace with trends through quick and cost-efficient development, Markus Fenn and Prof. Dr. Stefan May developed Eduard, a teaching and prototyping platform that can be used to map current trends.

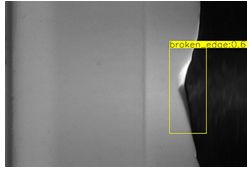

Utilizing AI in the Manufacturing Space

Our goal is to simplify AI so organizations can start deploying new technologies to save time and money. What we offer is a platform of AI and vision-based inspection and traceability apps that are easily customized

AI and AM: A Powerful Synergy

Artificial intelligence applied to designs of additively manufactured products goes beyond standard optimization to produce dramatic quality and performance gains in much less time

Security Must Be Addressed Before Autonomous Delivery Can Thrive

"Safety and security will serve as the bedrock and standard - not just for drone delivery, but for all autonomous delivery services," says Arrive CEO Dan O'Toole.

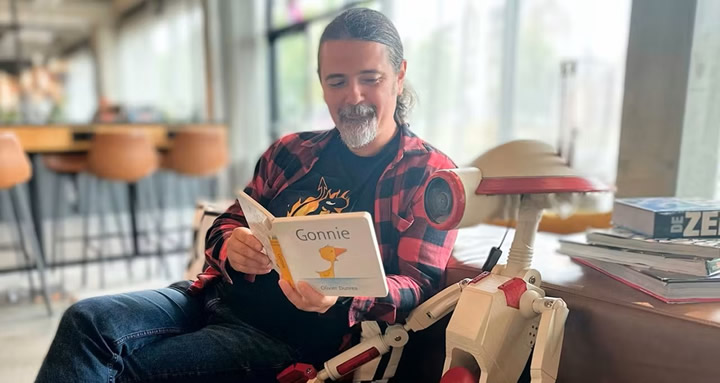

Meet the Maker: Developer Taps NVIDIA Jetson as Force Behind AI-Powered Pit Droid

Goran Vuksic brings the bot to tech conferences across Europe, demonstrating the power of the edge AI platform through a familiar 'Star Wars' figure.

Records 1 to 15 of 712

Featured Product

Piab's Kenos KCS Gripper

Piab's Kenos KCS gripper enables a collaborative robot to handle just about anything at any time. Combining Piab's proprietary air-driven COAX vacuum technology with an easily replaceable technical foam that molds itself around any surface or shape, the gripper can be used to safely grip, lift and handle any object. Standard interface (ISO) adapters enable the whole unit to be attached to any cobot type on the market with a body made in a lightweight 3D printed material. Approved by Universal Robots as a UR+ end effector.