FANUC America's Robot LINKi Zero Down Time Now Available to All Robotics Customers

Special Tradeshow Coverage for ATX West 2018

5 ways to advance robotics in manufacturing

Why Smart Manufacturing Is Guaranteed to Need Industrial Robotics

More production, more jobs? CMU pitches businesses on robotics in manufacturing

Special Tradeshow Coverage for Automate 2017

Robotics, Trump and Brexit turn up the heat amid the snow of Davos

Special Tradeshow Coverage for ATX West 2017

Boeing buys Liquid Robotics to boost autonomous surveillance at sea

Super Smart Society: Society 5.0

Special Tradeshow Coverage for The International Manufacturing Technology Show (IMTS 2016)

Do the benefits of robotics outweigh the heavy demands on infrastructure?

China's Big Bid For Germany's Industry 4.0 Technology

KUKA and Infosys Announce Industry 4.0 Partnership

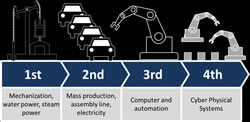

Why Everyone Must Get Ready For 4th Industrial Revolution

Records 16 to 30 of 38

First | Previous | Next | Last

Featured Product

Palladyne IQ - Unlocking new frontiers for robotic performance.

Robotics and Automation - Featured Company

.jpg)