Navigating the Shift: Industry 4.0 vs. Industry 5.0 - Welcoming the Next Wave of Innovation

Expanding on the foundational principles of the fourth industrial revolution, Industry 5.0 places a huge emphasis on fostering a flawless connection between machinery and humans.

Why Letting the Machines Do the Tending Will Open the Door to the Next Industrial Revolution

As anyone in the know can tell you, machine tending is incredibly important to the manufacturing process. A well-functioning manufacturing workflow relies on machinery consistently being loaded and unloaded with parts or materials.

Understanding the Role of Machine Vision in Industry 4.0

Today it is being applied to diverse areas such as monitoring processes for predictive maintenance, and robotic guidance that makes it possible for robots to safely work with and respond to human interactions.

2022 Top Article - Wireless Charging Enables Industry 4.0 Implementation with Mobile Robots

The latest wireless charging solutions use techniques based on the principle of electromagnetic induction. When an alternating current is passed through an induction coil on the transmitter side, an oscillating magnetic field is created.

2021 Top Article - Sustainable Supply Chains in the Era of Industry 4.0

Because supply chains consume resources on a large scale, they are responsible for a disproportionately large share of the world's carbon emissions.

Robotics Changed Industry 4.0; Now, How Will Industry 4.0 Change Robotics?

This is how Industry 4.0 technology is revolutionizing the robotics industry - and what changes robotics professionals should expect over the next few years.

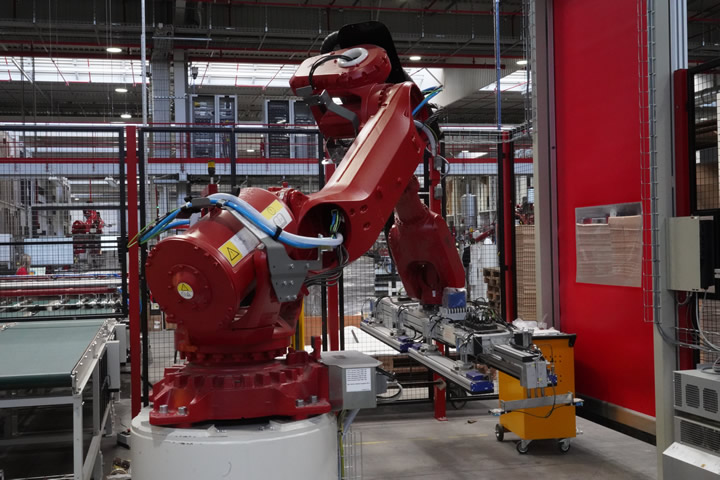

Robotics in Woodworking - The Zimmer Group reaches deep into its bag of tricks for Schmidt

The manufacturer of the robot processing cell is the Zimmer Group from Rheinau in Germany. On its way towards Industry 4.0, the Zimmer Group has evolved from a classic component supplier to a system provider and has thus produced an entire robotic cell at once.

Intelligent Image Processing Supports Production Workers in Industrial 4.0 Applications

Automation plays a major role in Industry 4.0. Cost reduction, increased productivity and zero-defect quality are factors that are increasingly prompting companies to digitalize their processes. But often full automation also means high investments.

Intelligent Robot Vision Solutions for Your Industry 4.0 Processes

Vision systems from SICK enable flexible automation for positioning, inspection, and measurement tasks. It also promotes the use of collaborative robots or "cobots" as a means to effective and safe human-robot collaboration.

Industry 4.0 Leaders Launch Musashi AI Consortium, demonstrate first AI prototypes

Musashi AI consortium is a direct result of this need and is focused on enabling the manufacturing industry to take massive leaps forward to reach the full potential that AI and the smart factory will bring to bear.

The cornerstones of Zimmer Group's Industry 4.0 success in production

Zimmer Group has consistently and successfully oriented their mechatronic component portfolio towards Industry 4.0. These range from electric mid-class grippers for standard applications to motor spindles for chipping wood, plastic and metal, to high end products.

Smart Pumps & Industry 4.0

By updating their pneumatic system and the materials used to handle the blanks, Smart Pumps connected to IOLink Masters or similar communication devices, can bring smart feedback to existing press operators.

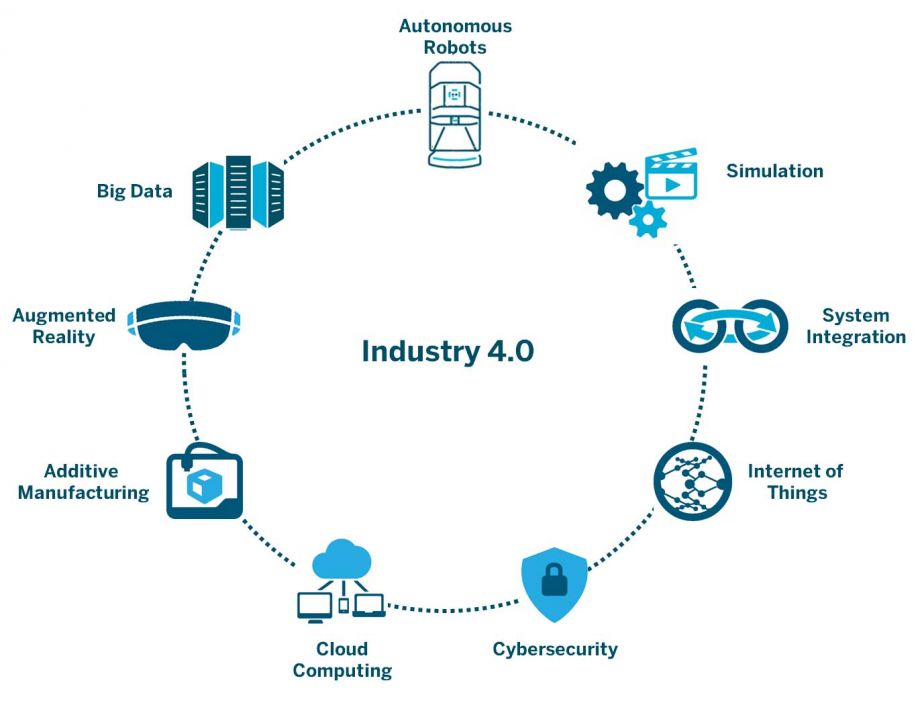

What Industry 4.0 Means for Manufacturers

Industry 4.0 represents a giant leap in the evolution of machines - an evolution that has already pioneered leaps in productivity and quality of life over several hundred years. Today, our machines are connected with each other, their physical environments, and to people

A Prime Example for Industry 4.0

The iTENDO is the worlds first intelligent toolholder with real-time process control. In an interview, developers Friedrich Bleicher and Johannes Ketterer explain how the embedded systems solution makes production smart and economical.

Removing the Roadblocks of Machine to Machine Communication in Manufacturing

Solving the challenge of data interoperability exists for the IT function in many situations. For the connected factory this means enabling the flow of information between machines, which in the past has been easier said than done.

Records 1 to 15 of 38

Featured Product

ResinDek TRIGARD ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC (www.resindek.com) created the TriGard ESD Ultra finish for its ResinDek engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Robotics and Automation - Featured Company

US Digital

US Digital's breadth of quality motion control products offers a range of sizes and CPRs, delivering the position accuracy you demand. With over 1 million off-the-shelf configurations, including custom designs and manufacturing, we put ultimate precision into your application. US Digital has delivered quality in motion since 1980. Located in Vancouver, WA, the vertically integrated facility and the stellar service team offer shorter lead times, with same-day fulfillment on most orders.

.jpg)