Robots Automate Machine Tools

Case Study from Zimmer Group - Using an Assistant for Door Removal

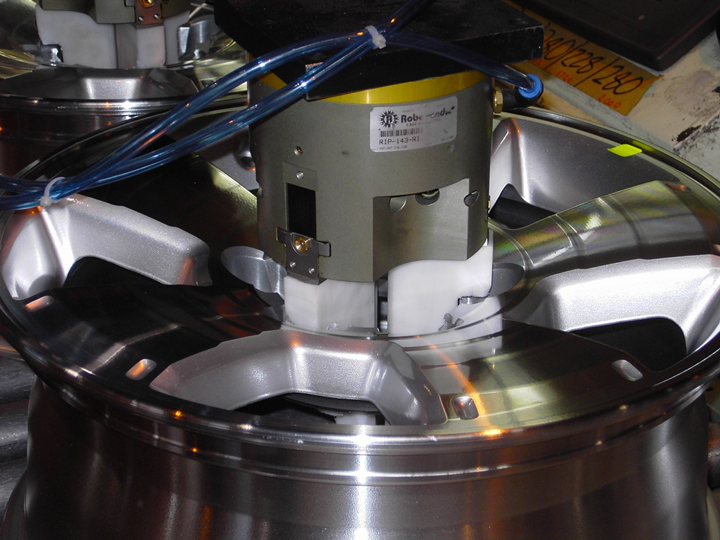

Grinding and Deburring in a Foundry - standard grippers from the Zimmer Group

Questions to Ask Before Selecting Your Air Gripper

MODEX Q&A - Schmalz

A Guide to Self-Healing Robots

Pick, Purchase and Program Your First Industrial Robot

FT-Produktion Boosts Output Capacity Without Adding Personnel by Employing Combination of Collaborative Robots and Robot Grippers

Study: A robot with a firm yet gentle grasp

Solve Loading Dock Challenges With Robotic Unloading

New Collaborative Robot Vacuum Tool

Looking for a Robotic Gripper?

ASU's Southwest Robotics Symposium previews the new technology guiding the next wave of human-robot interaction

Know What To Consider When Selecting The Proper Gripper

Electric Grippers

Records 31 to 45 of 65

First | Previous | Next | Last

Featured Product

3MP HDR IP69K Camera for Robotics & Autonomous Vehicles

Robotics and Automation - Featured Company