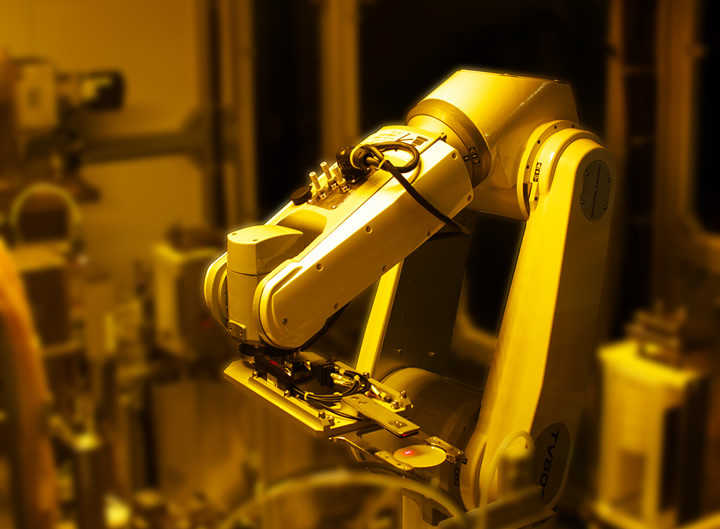

Contamination-free automation

Variance and Volume Advantageously Combined One of a Kind in Series

Labor Shortages Impact on the Automation in the eCommerce Boom

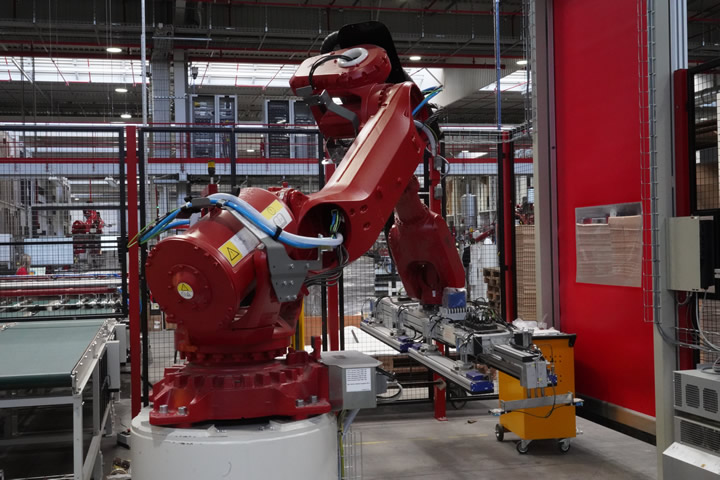

Zimmer Group Supports Vischer & Bolli Robot Cell With Kuka Robots and a Bespoke Gripper

Zimmer Group System Technology - Development Competence at Just the Right Time

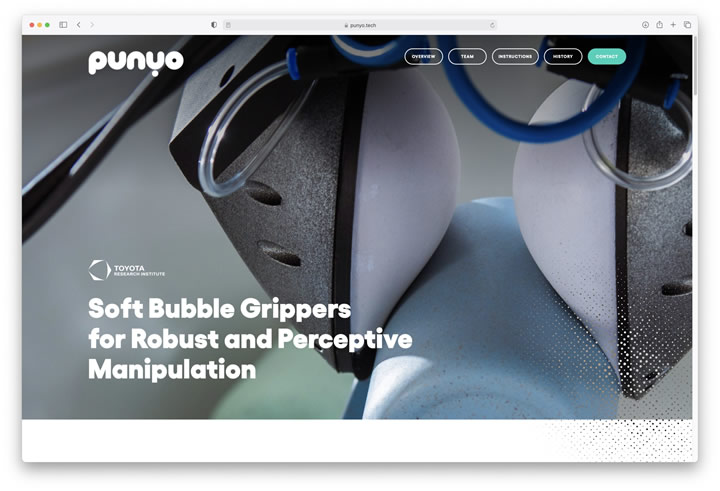

Toyota Research Institute Shares Design to Help Advance the Field of Soft Robotics

Robotics in Woodworking - The Zimmer Group reaches deep into its bag of tricks for Schmidt

Grasping Static Electricity for Revolutionary Robotics - Nike-backed Start-up Automates the Impossible

Axis compensation module from the XYR1000-B series with new linear guide and new installation sizes

Bringing Handling Technology to Life

Coval introduces a vacuum chamber for gripping protective masks

Robots in the factory: bosses or slaves?

Advantages of Vacuum driven Soft Grips for Food Production

New Robotic Grippers Transforming the Food Sector

Grasping Static Electricity for Revolutionary Robotics

Records 16 to 30 of 65

First | Previous | Next | Last

Featured Product

Harmonic Drive - Coming Soon! Integrated Actuators with EtherCAT

Robotics and Automation - Featured Company

.jpg)