Aerospace's Automation Breakthrough: How Robotics and AI Orchestration Are Rewriting the Supply Chain

For aerospace, the next leap will come from integrating physical automation with AI systems capable of coordinating the flow of information across complex, multi-vendor, secure environments that protect confidential information all while transforming efficiency..

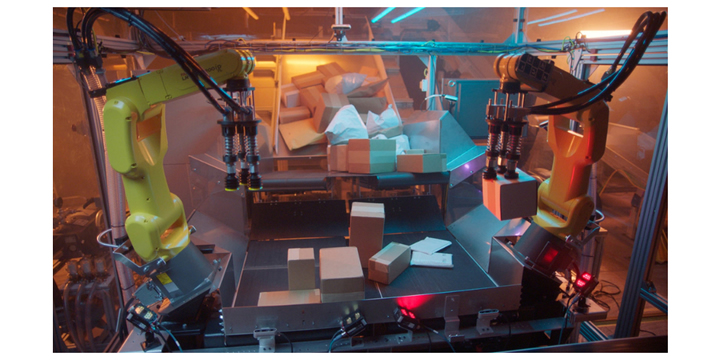

How to Improve Warehouse Picking Speed with Automation

In warehousing, distribution, and e-commerce fulfillment centers, operational and customer success relies on fast and accurate fulfillment, but achieving and maintaining this service level can be challenging.

Building a Better RFP: A Practical Guide to Choosing the Right Automation Partner

Investing in automation is a major decision - one that affects everything from operational efficiency to customer satisfaction. But before you can reap the benefits, you need the right partner. And that starts with a solid Request for Proposal (RFP).

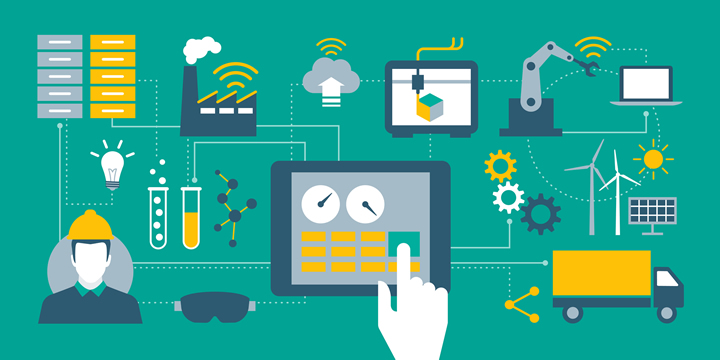

What Role Does Robotics Play in the Manufacturing Supply Chain?

Robotics has moved from "point fixes" on isolated stations to the connective tissue of the entire supply chain. In practical terms, that means robots are continuously progressing from just weld or pick.

Exploring the Future of Supply Chain in 2025

Many of the changes that will impact supply chains in 2025 are not new, but the frequency and intensity has the potential to bring new levels of strain to already stretched supply chains. So, what can companies do to prepare for 2025 and beyond?

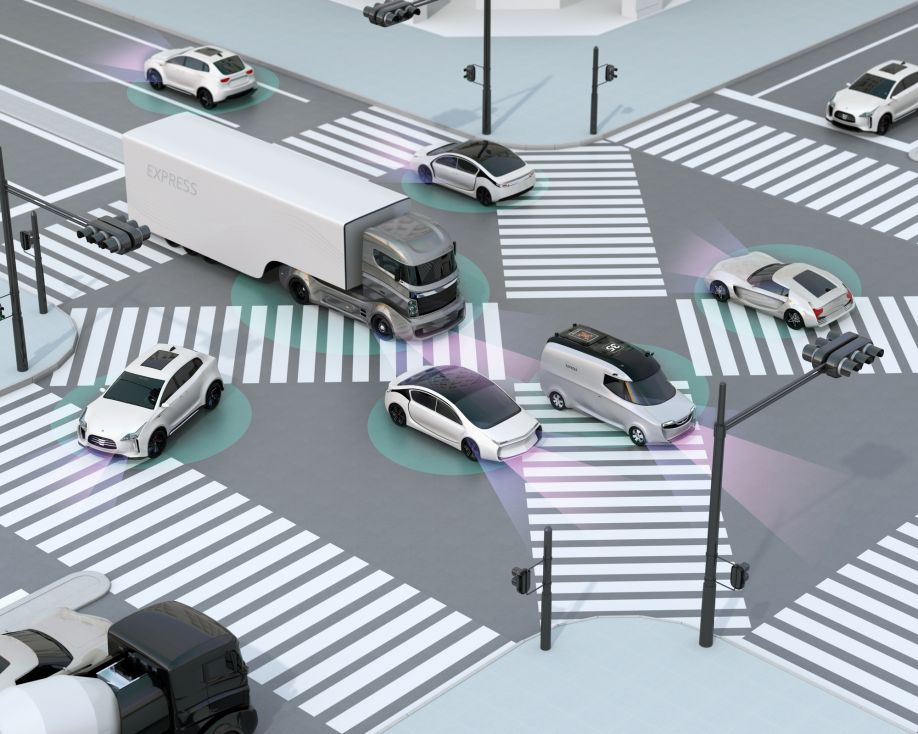

AI Route Optimization Saves Money, Cuts Fuel Consumption and Provides Faster Delivery Times

Amazon, which pioneered same-day delivery, uses an AI system that requires digesting a huge amount of data to determine the best routes to avoid traffic and get the driver to your home in the fastest possible time.

Mastering peak season with robotics & automation

This year, continued economic uncertainty and geopolitical disruption are once again complicating peak season planning, compounded by the ongoing industry-wide labor shortage which makes it harder to scale the workforce fast enough to meet demand.

The Role of Automation in Supply Chain Resilience

While automation offers significant benefits for enhancing supply chain resilience, it also comes with challenges and considerations that businesses must address to ensure successful implementation.

Shop Floor Scheduling: Are You Getting the Most out of Your Plant's Production Capacity?

By leveraging modern production scheduling tools, you can ensure your operations are not only efficient but also adaptable to the dynamic demands of the industry.

What role does automation play in the manufacturing supply chain?

Adrian Wood, Strategic Business Development Director at DELMIA, gives us some very informative and interesting insights into automation's integral role in the manufacturing supply chain.

AI-Powered Kindred INDUCT Automates Induction of One Million Items with 95% Accuracy

An INDUCT workcell was incorporated into an existing induction line at a global logistics facility and transportation hub where 200,000 small parcels are sorted each hour, and up to 400,000 parcels are processed during the peak holiday season.

5 Transportation Solutions for Fragile Robots

Businesses may need to move robots for one of many reasons. They could move to a new facility, place some robots in storage during slow seasons or have to move newly purchased machines themselves.

Automation Is a Game Changer for Supply Chains

That's not to say the entire supply chain, from end to end, will be automated in full. There will always be people involved in its operations. However, some degree of automation is essential to keeping things moving.

Berkshire Grey and FedEx Expand Their Robotic Automation Solutions Relationship

The new product development agreement is an expansion of this collaboration and offers new opportunities for the two companies to work together to further increase efficiencies across the FedEx enterprise using AI-enabled robotic automation.

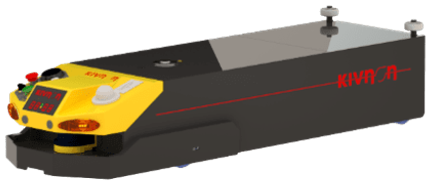

AGV Selection Process for 2022 Must Start with Delivery Commitment Guarantee

Throughout industrial manufacturing, distribution, and logistics the lead time from many AGV manufacturers is more than a year. That means product ordered in Q1 2022 will not be delivered until the following year.

Records 1 to 15 of 50

Featured Product

New incremental encoder IERF3 L from FAULHABER

FAULHABER is expanding its product range with the ultra-precise incremental encoder IERF3 L. Thanks to the optical measuring principle and state-of-the-art chip technology, the device offers the highest resolution, excellent repeatability, and outstanding signal quality. In typical applications, the positioning accuracy is 0.1° and the repeatability 0.007°. This makes the encoder the perfect solution for high-precision positioning applications in confined spaces.

Robotics and Automation - Featured Company

Harmonic Drive LLC

Harmonic Drive LLC (HDLLC) designs and manufactures precision servo actuators, gearheads and gear components. Harmonic Drive® gears play critical roles in robotics, medical diagnostics and surgical robotics. We work with industry-leading customers and companies of all sizes to provide both standard product and custom-engineered solutions. The majority of the products sold by HDLLC are proudly made at our US headquarters and manufacturing facility in Massachusetts.

.jpg)

.jpg)