Fully Autonomous Deliveries inside Multi-floor Buildings without Elevator APIs

Once a robot can move between floors without any changes to existing building infrastructure, operators get immediate ROI by freeing staff from repetitive delivery work while improving speed and convenience for residents and guests.

How to Build a Digital Foundation for Your Robotics and Automation Strategy

A strong digital foundation brings everything together, allowing automation initiatives to scale, adapt and perform as intended. Without it, automation efforts often stall before they reach their full potential.

Facility Maintenance: Lavo Bot AI and NVIDIA Bring Autonomy to Exterior Surface Cleaning

Equipped with advanced mapping, multi-sensor vision and zone-based safety, the system navigates real-job sites with confidence—handling up to 6,000 sq ft/hour and supporting pressure-wash rigs up to 12 GPM and 4,500 PSI.

Physical AI and Autonomy in the Construction Industry

Bedrock is taking advantage of the dramatic accessibility of GPUs and frameworks for scaled data access and training, combining it with our unique understanding of how to build and create autonomy solutions quickly and efficiently.

The Future of Autonomous and Wireless Charging

The real driver of change has been the need to reduce manual intervention and lower operational costs. When a robot can charge itself safely and autonomously, maintenance downtime drops dramatically, and so does total cost of ownership.

European researchers developed energy-efficient machine vision inspired by human eyesight and the brain

This enables, for instance, intelligent robots and drones that can operate independently in a rescue mission after an earthquake without constant network connections or bulky batteries.

2025 Top Article - ANYbotics ANYmal robot is addressing key challenges in Industrial Robotics

The ANYmal robot addresses key challenges in industrial operations by offering autonomous, highly mobile inspection capabilities in complex and hazardous environments. Its four-legged design enables navigation through uneven terrains, stairs, and confined spaces.

2025 Top Article - Purpose-Built, Specialized Robots are the Future

Wheeled robots like ours are more efficient for the same reason cycling is more efficient than running, which includes less of a fight with gravity. The efficiency, as well as the sheer complexity of humanoid robots adds up to something that may be very much higher cost.

2025 Top Article - The Ultimate Guide to Depth Perception and 3D Imaging Technologies

Depth perception helps mimic natural spatial awareness by determining how far or close objects are, which makes it invaluable for 3D imaging systems. Get expert insights on how depth perception works, the cues involved, as well as the various types of depth sensing cameras.

The Hiring Freeze Came First. The Robots Came After.

This is not just a vibes-based assessment: in May, the U.S. reported around 332,000 open jobs in transportation, warehousing, and utilities, plus another 400,000 in manufacturing. Wages are up, benefits are better, yet demand still outpaces supply.

ReBeLMove Pro: modular robot platform for logistics, assembly and handling

Autonomous mobile robot from igus promises simple configuration with flexible superstructures and easy commissioning

How U.S. Manufacturing VPs Can Close the Execution Gap — The New Playbook for Operational Excellence

Operational excellence used to mean efficiency. Now, it means consistency.

In a volatile manufacturing environment, the winners aren't those with the best machines or biggest budgets — they're the ones who can execute the same playbook flawlessly, every day, on every line.

The Right 3D Vision Scanner for Robotic Programming: Laser Profilers vs Structured Light Scanners in Industrial Automation

By combining flexible vision technology with automated processing, manufacturers and system integrators can shorten deployment cycles, reduce reliance on fixtures, and achieve the adaptability needed for high-mix, high-precision production.

ATEC2025·Real-World Extreme Challenge Concludes with Zhejiang University Team Claiming $150,000 Prize for Breakthrough in Fully Autonomous Robotics

Thirteen global teams push the boundaries of "no remote control" robotics, driving the evolution from teleoperated tools to autonomous agents

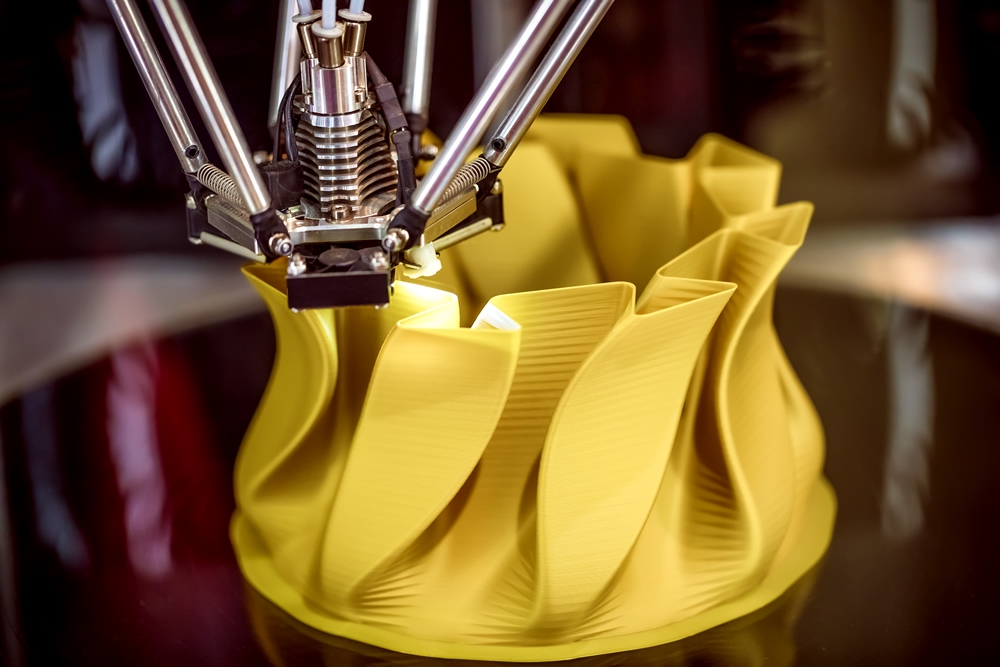

What are the motion control requirements for additive manufacturing machines?

3D printed objects can include intricate machine components, through to edible items, and as a result, the additive material could range from powdered metals to chocolate. Whatever the material and shape required, functionally, the 3D printing technique is the same.

Records 1 to 15 of 1265

Featured Product

PI USA - Gantry Stages for Laser Machining and Additive Manufacturing

High performance gantry systems, from PI, are used in precision assembly, laser machining, and additive manufacturing. Complete with software and state-of-the-art EtherCat® motion controllers. Easy to program, easy synchronization with lasers and dispensers. Standard and custom, compact systems and large, granite-based units.

Robotics and Automation - Featured Company

Palladyne AI Corp.

Welcome to Palladyne AI, where we unleash the power of robotics with our revolutionary AI software platform for the physical world. In a world where robots are progressing toward human-like adaptability, seamlessly navigating dynamic environments and conquering complex tasks with unparalleled efficiency, Palladyne AI stands as the beacon of innovation toward that future reality. Through our cutting-edge artificial intelligence (AI) software platform, we are redefining the boundaries of robotics. Our goal is simple: Help companies with autonomy in their robotics operations by addressing key challenges of traditional robotic deployments.