International robotic safety conference 2025: Key takeaways shaping the future of safe automation

The International Robotic Safety Conference highlighted how rapidly the safety environment is evolving, driven by new standards that reflect innovative robotics technologies and tightening global regulations.

Explosion-Proof Robotics in ATEX/IECEx Environments: Progress, Challenges and Practical Pathways

Industrial robotics has transformed manufacturing, logistics and maintenance across countless sectors. Yet in potentially explosive environments such as refineries, petrochemical plants, offshore platforms and battery production facilities, the picture changes dramatically.

Humanoids - Safety Standards for the Next Wave of Robots

Today's safety concerns generally boil down to physical component and perception issues. If a robot is in a rugged environment, hardware components degrade and can lead to dangerous malfunctions.

How Does Zero Trust Apply to Robotics?

By hardening your endpoints, securing your software supply chain and enforcing continuous verification, zero trust closes the most common attack paths long before they can be exploited, from development to deployment.

AUVSI Launches "Trusted UGV" Cybersecurity and Supply Chain Certification at XPONENTIAL 2025

As UGVs are increasingly deployed across a wide range of use cases-from defense and public safety missions to critical infrastructure inspection -their reliance on software, sensors, and connectivity makes them increasingly vulnerable to cyber threats and supply chain risks.

Interoperability, the VDA5050 Standard and MiR's approach

The VDA5050 standard is one of the industry's attempts to address this challenge by standardizing communication between multiple different robot types from various suppliers using a common control system.

Averting Factory Fires, Diminishing Downtime: How Thermal Imaging is Safeguarding International Production Lines

The system required a bespoke interface that could accurately test each battery for thermal runaway, and then export and transmit the data to a server to be cross-referenced and analyzed where anomalies were found to be present.

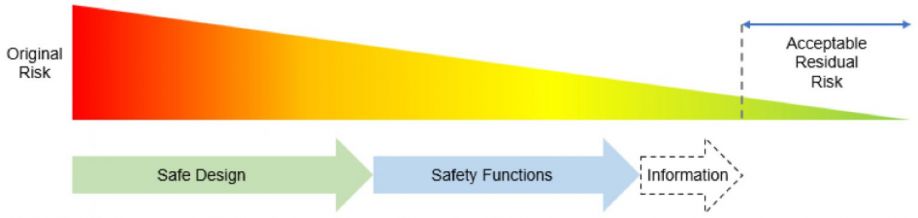

Machine Functional Safety - PL and SIL Ratings

This paper reviews the concept of Functional Safety as it relates to machinery. The design steps for a safe machine are outlined and the methodology for determining appropriate PL/SIL safety ratings discussed.

Forklift Accident Prevention: Understanding Risks and Enhancing Safety

Let's examine the risks associated with forklift operations and look at ways to use safety protocols and smart technology to enhance workplace safety and prevent forklift accidents.

ANSI/A3 R15.08-2 Safety Standard for Industrial Mobile Robot Systems and Applications Now Available

R15.08-2, the American National Standard for Industrial Mobile Robots (IMRs) - Safety Requirements - Part 2: Requirements for IMR system(s) and IMR application(s) provides safety requirements for deploying IMR systems into an industrial environment.

Global Standards for Commercial Robotics

Every business should understand the international standards for commercial robotics and the key organizations and global markets related to them. Companies in every industry worldwide are currently reaping the benefits of automation.

Safely Integrating Robots and AI Into Your Warehouse Workforce

While integrating robots and AI into our warehouses can help with production and quality assurance, care must be taken when this tech is first introduced. Managers need to familiarize their employees with these innovations..

Following the Path to AGV Safety

Although automated guided vehicles (AGVs) are, by definition, designed to run autonomously, they usually need to collaborate with people and therefore move, and react, in a safe, predictable manner.

Opinion: EU AI Act Will Stifle Robotics Innovation

Any policy that slows down the use of automation will cause operational inefficiencies. This is the last thing we need considering the global supply chain crisis.

2021 Top Article - How a Team United in Just 18 Months to Overhaul How America Destroys Its Most Dangerous Chemical Weapons

CRG Automation and its team of engineers - with specialties such as mechanical, electrical and controls -began devising custom engineered solutions, often incorporating

advanced robotics.

Records 1 to 15 of 48

Featured Product

High Performance Servo Drives for localized and distributed control applications from Servo2Go.com

Engineered to drive brushless and brush servomotors in torque, velocity or position mode, Servo2Go.com offers a broad selection of servo drives in a wide range of input voltages and output power levels.

Robotics and Automation - Featured Company

Encoder Products Company

At Encoder Products Company, we specialize in the encoders that provide you with motion feedback. EPC has been a leading designer and manufacturer of motion sensing devices for more than 50 years, we understand that each industrial automation application is different, and you need encoders that fit the needs of your applications. Our encoders are highly configurable, offer an array of shaft or bore sizes, output types, connector types, mounting options, and resolutions as high as 65,536 CPR.

.jpg)

.jpg)