Productivity Inc. Wants Your Robot to Do More

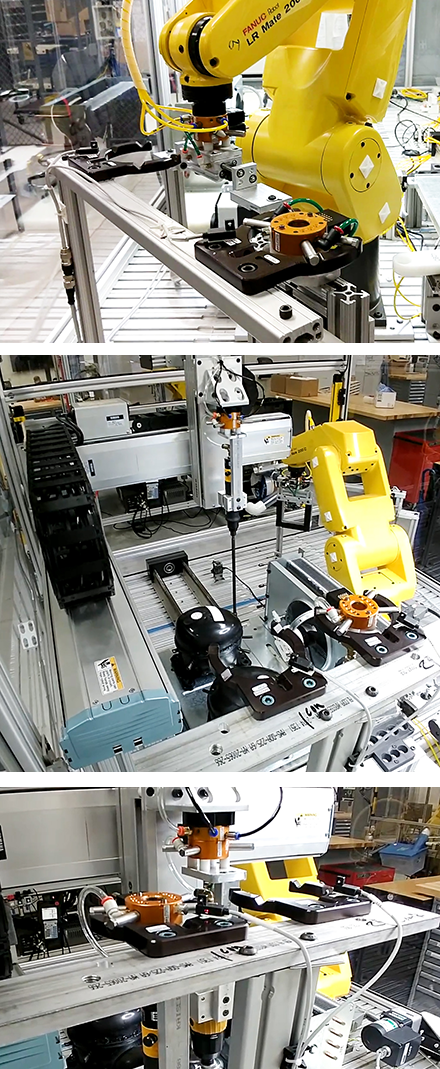

Using ATI's QC-11 Tool Changer and RCT-151 Radially-Compliant Deburring Tool along with a Renishaw probe, they produced a demonstration highlighting their expertise in aiding potential customers to maximize productivity of the robots already installed in their facilities

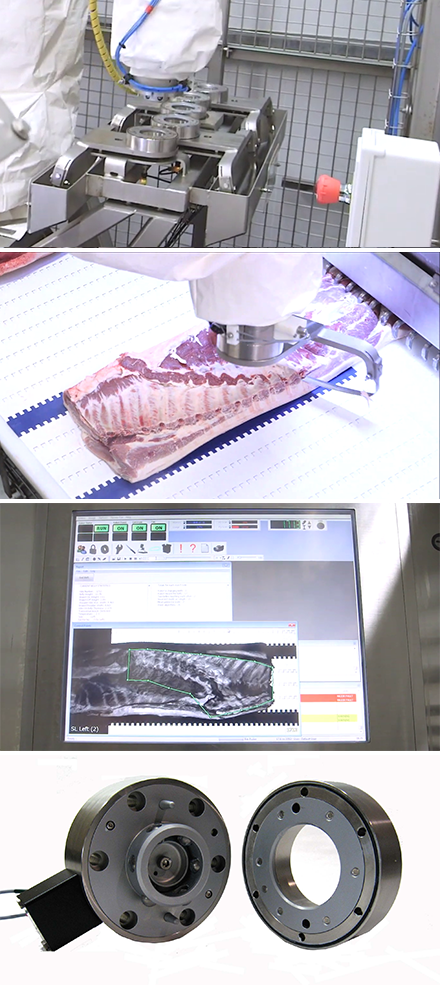

Frontmatec Food Handling with Stainless Steel ATI Tool Changers

Robots are better suited to the harsh temperatures and repetitive work than humans are, and with the right programming and end-of-arm-tools, they can provide more repeatable results.

Staubli Rolls Out 5 New Models of Robotic Tool Changers

Last month, Stäubli introduced 5 new models of tool changers to round out our MPS product line. These new models open up much of the smaller payload robots to using tool changers.

Automated Inspection with Automatic Tool Changers

Using ATI's QC-11 Tool Changer and Tool Stands, the Autocalibration Kit enables each system to recalibrate before moving on to the next inspection job.

Güdel Integrates Tool Changers in Multi-Purpose Metal Forming Solution

When separating aluminum sheets prior to loading into the press, they can stick together due to a suction effect that occurs as the sheets are lifted. Most methods for destacking aluminum are very slow compared to steel destacking ...

Madison College Takes ATI Tool Changers to School

Wisconsin's Madison College is home to the Automated Manufacturing Systems Training (AMST) Program. Students in the AMST program develop competencies in a wide array of automation areas..

Stäubli robotic tool change systems, quality you can count on

Recently Stäubli introduced two compact fully automatic tool change systems, the MPS 130 and the MPS 260, for the medium payload segment, Stäubli Connectors rounds off the lower end of its existing series.

Case Study: ATI Tool Changers Transform Schmalz's Design-Test Center

Without tool changers, we have to manually detach the tool from the robot with bolts and thumbscrews, wheel the tool away on a cart, and attach a new tool the same way. This is tedious and not possible for one person to do by themselves.

ST Robotics Announces new Passive Tool Changer System

ST Robotics has announced today the release of its new passive tool changer system, the TC12, an innovative changer that requires no compressed air or electrics to operate, for the ST Robotics R12 five and six-axis articulated robot arms.

Records 1 to 9 of 9

Featured Product

MVTec MERLIC 5.8

With MERLIC 5.8, MVTec expands its easy-to-use machine vision software. The latest version improves process reliability beyond pure image processing, offering enhanced error handling and optimized configuration. This enables faster setup and stable deployment across diverse production environments. Explore MERLIC 5.8 now

Robotics and Automation - Featured Company

PDS / Precision Drive Systems

Over 40,000 Spindles Repaired or Rebuilt Since 1996. PDS is a global leader in spindle repairs and retrofits for precision metal and robotics applications. With over 40,000 spindles repaired to better than-new-condition. PDS also offers new spindles, CNC accessories, and Industry 4.0 spindle monitoring. With offices in Bessemer City, NC (near Charlotte) and Herford, Germany PDS backs superb craftsmanship with a standard 12 month warranty on repaired spindles and an optional, industry-leading 24 month PrecisionCare warranty.

.jpg)