The Future of Autonomous and Wireless Charging

The real driver of change has been the need to reduce manual intervention and lower operational costs. When a robot can charge itself safely and autonomously, maintenance downtime drops dramatically, and so does total cost of ownership.

2025 Top Article - ANYbotics ANYmal robot is addressing key challenges in Industrial Robotics

The ANYmal robot addresses key challenges in industrial operations by offering autonomous, highly mobile inspection capabilities in complex and hazardous environments. Its four-legged design enables navigation through uneven terrains, stairs, and confined spaces.

2025 Top Article - Redefining industries with robotics and AI

While robotics have been a staple in the automotive manufacturing industry for decades, the applications have now spread far beyond, reshaping industries from agriculture to healthcare and service industries.

2025 Top Article - Purpose-Built, Specialized Robots are the Future

Wheeled robots like ours are more efficient for the same reason cycling is more efficient than running, which includes less of a fight with gravity. The efficiency, as well as the sheer complexity of humanoid robots adds up to something that may be very much higher cost.

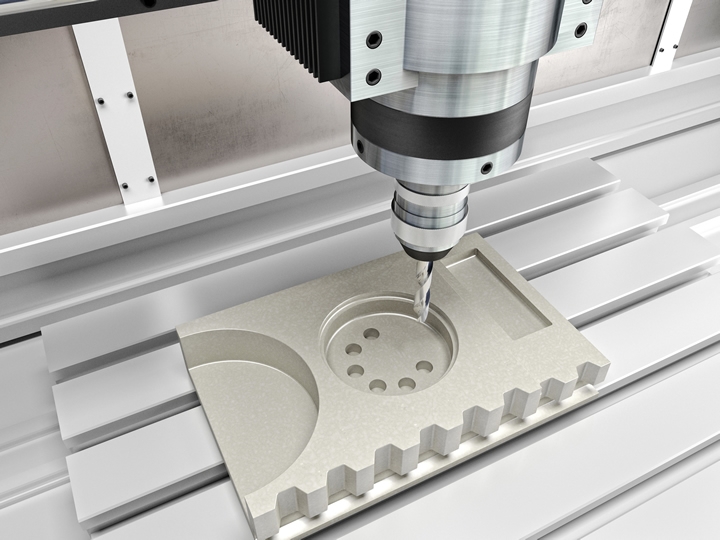

2025 Top Article - The Future of Machining: Key Trends and Innovations

AI and robotics are seen to deeply disturb specialized industry sectors, bringing beneficial pioneering modernizations in machining, industrial manufacturing and machine shops. Elitsa Krumova explores the future of machining in more depth on behalf of DELMIA.

2025 Top Article - The Ultimate Guide to Depth Perception and 3D Imaging Technologies

Depth perception helps mimic natural spatial awareness by determining how far or close objects are, which makes it invaluable for 3D imaging systems. Get expert insights on how depth perception works, the cues involved, as well as the various types of depth sensing cameras.

StackTrax - The Industry's First Off-The-Shelf Dual Axis RTU

Compared to alternative solutions, such as multiple robots or overhead gantry systems, StackTrax can provide a space and cost-saving alternative that will improve cycle time and overall throughput.

CASE STUDY STT SYSTEMS and STEMMER IMAGING: AUTOMOTIVE BOLT INSPECTION SYSTEM WITH GOCATOR SMART 3D LASER PROFILERS

LMI Technologies, in partnership with STT Systems and Stemmer Imaging, implemented an automated quality inspection system to detect missing bolts on automotive blanks. The system integrated multiple Gocator 3D sensors and an RFID tracking system for real-time analysis.

How U.S. Manufacturing VPs Can Close the Execution Gap — The New Playbook for Operational Excellence

Operational excellence used to mean efficiency. Now, it means consistency.

In a volatile manufacturing environment, the winners aren't those with the best machines or biggest budgets — they're the ones who can execute the same playbook flawlessly, every day, on every line.

The Right 3D Vision Scanner for Robotic Programming: Laser Profilers vs Structured Light Scanners in Industrial Automation

By combining flexible vision technology with automated processing, manufacturers and system integrators can shorten deployment cycles, reduce reliance on fixtures, and achieve the adaptability needed for high-mix, high-precision production.

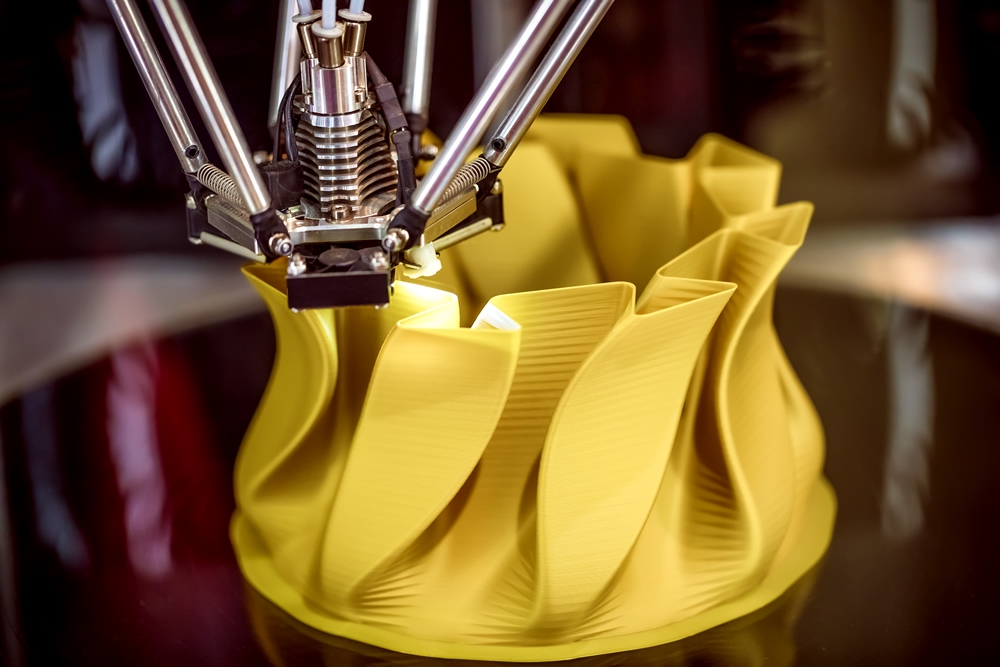

What are the motion control requirements for additive manufacturing machines?

3D printed objects can include intricate machine components, through to edible items, and as a result, the additive material could range from powdered metals to chocolate. Whatever the material and shape required, functionally, the 3D printing technique is the same.

What is Agentic AI and is it here to stay?

Agentic AI is another concept that is slowly entering the vocabulary of professionals and the warehousing industry. How can it be used efficiently in the market, for what purposes, and what would be a potential timeline for adoption?

Automation Solutions Mergers & Acquisitions Update

Bundy Group is an investment banking and Mergers & Acquisitions advisory specialist that has specialized in the automation and industrial technology markets for over 16 years.

How LAPP Rebuilt Its Inventory Process with Autonomous Drones

For LAPP USA, Corvus One turned a labor-intensive, error-prone process into a nightly automated workflow that provides reliable visibility, reduces costs, and improves customer service.

Sonair's ADAR 3D Ultrasonic Sensor

ADAR stands out by combining full-3D sensing via ultra-sound, strong safety credentials, cost efficiency and ease of integration. This is enabling robots to safely work in closer proximity to people and in tougher environments than many existing solutions.

Records 1 to 15 of 2059

Featured Product

3D Vision: Ensenso B now also available as a mono version!

This compact 3D camera series combines a very short working distance, a large field of view and a high depth of field - perfect for bin picking applications. With its ability to capture multiple objects over a large area, it can help robots empty containers more efficiently. Now available from IDS Imaging Development Systems. In the color version of the Ensenso B, the stereo system is equipped with two RGB image sensors. This saves additional sensors and reduces installation space and hardware costs. Now, you can also choose your model to be equipped with two 5 MP mono sensors, achieving impressively high spatial precision. With enhanced sharpness and accuracy, you can tackle applications where absolute precision is essential. The great strength of the Ensenso B lies in the very precise detection of objects at close range. It offers a wide field of view and an impressively high depth of field. This means that the area in which an object is in focus is unusually large. At a distance of 30 centimetres between the camera and the object, the Z-accuracy is approx. 0.1 millimetres. The maximum working distance is 2 meters. This 3D camera series complies with protection class IP65/67 and is ideal for use in industrial environments.

Robotics and Automation - Featured Company

Onward Robotics

Onward Robotics delivers innovative automation technology that coordinates humans and robots as a cohesive system to revolutionize fulfillment. Our Meet Me® solution combines proprietary software with person-to-goods mobile robots to increase efficiency in warehousing, distribution, and e-commerce operations. Onward Robotics provides the boost in productivity, flexibility, and speed that companies need to remain competitive and grow.