Maximizing ROI for Mobile Robots: A Systems Strategy

Fostering Innovation: The Keys to Success

Why Do Hardware Startups Fail?

Addressing the Skills Gap in Manufacturing through Robotics Training

Women in Engineering: Embracing Diversity & Encouraging Passion to Optimize Outcomes

Top Viewed Articles of 2023

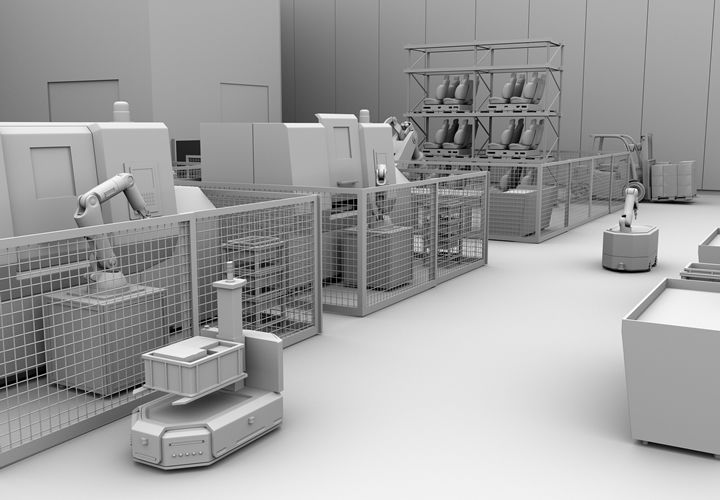

Trends in Industrial Robotics to Watch in 2024

Why Industrial Robotics is Experiencing Steady Growth

What's Holding Back Robot Adoption? - With the UK Lagging Behind Its Competitors, What Needs to Change?

ABB to invest $280 million in its European Robotics hub in Sweden

Faulhaber - New building with diverse production possibilities

Renaissance of Robotics: The Top 10 Marvels in the Post-COVID Age

10 Key Questions to Evaluate AI-Powered Automation

The Top 5 Things Every Manufacturing CIO Should Know

Robotics In Manufacturing: Threat or Opportunity?

Records 16 to 30 of 149

First | Previous | Next | Last

Featured Product

IP Seals for Robots

Robotics and Automation - Featured Company

.jpg)