Making cheddar With Industrial Automation - Achieving 83 Per Cent Waste Reduction in Food Manufacturing

Ultrasonic uses energy from microscopic vibrations of a blade to pass easily through the material and offers a more effective solution for cutting cheese and other food products. When paired with automation, ultrasonic technology can deliver precise and accurate cutting.

How Top Modules Make AMRs Possible

An AMR without a top module is like a robotic arm without an end-effector tool such as a gripper-it lacks functionality. The benefits of AMRs are only realized-and maximized-with top modules and high-quality gates and carts that transfer the transported materials.

New Robotic Grippers Transforming the Food Sector

While traditional robotics systems have successfully served the food sector for many years in palletizing (and some packaging) applications, it is only in recent years that it has become possible for robots to handle delicate food items directly.

Questions to Ask Before Selecting Your Air Gripper

The array of gripper choices in the automotive, pharmaceutical and electronics and industries for pick-and-place automation systems are numerous. The many gripper styles - all of which have their own size, method of operation, and level of human interaction - is daunting.

The Incredible Potential of Soft Robotics

Alternatives to hard components hold potential for applications from surgery to space exploration

MODEX Q&A - PIAB

We have developed specialized lifting solutions to solve the problems with repetitive strain injuries of manual handling in most of the areas in a Distribution Center (receiving dock, storage area, picking area, shipping dock). Booth #2602

Food Safety in Large Scale Picking of Produce

We've talked with many customers who struggled with the cleaning and waste associated with vacuum-based EOAT systems. The air these systems use to attach to a food item is sucked back into the device - and along with it, food particles.

Discussing ATX West with ATI Industrial Automation

"Customers continue to shift toward more flexible solutions to support a variety of tasks. ATI's product families are configured to order and designed to increase process flexibility." Booth #4411

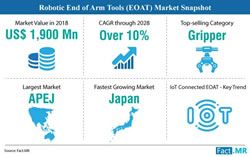

Robotic End of Arm Tools (EOAT) Market Size will Grow at a Lucrative CAGR of 10% by 2028, Fact.MR Study

A recent research study by Fact.MR estimates global sales of robotic end of arm tools (EOAT) to surpass US$ 2,000 Mn in 2019, up from US$ 1, 900.3 Mn in 2018. This growth in sales can be attributed to the ever-evolving demand of industrial ecosystems for high productivity.

Robot End-Effector Market to Reach US$ 6.5 Bn by 2025

The food & beverage industry will provide attractive growth potential to the market. The Automated Guided Vehicles (AGVs) or Automated mobile Robots (AMR) are highly suitable for materials shifting operations in the food manufacturing companies.

Benefits of Collaborative Robots

It is true that a collaborative robot is designed to work without additional physical guarding like fencing. But the robot is rarely a lone component in a system.

Records 16 to 26 of 26

Featured Product

New incremental encoder IERF3 L from FAULHABER

FAULHABER is expanding its product range with the ultra-precise incremental encoder IERF3 L. Thanks to the optical measuring principle and state-of-the-art chip technology, the device offers the highest resolution, excellent repeatability, and outstanding signal quality. In typical applications, the positioning accuracy is 0.1° and the repeatability 0.007°. This makes the encoder the perfect solution for high-precision positioning applications in confined spaces.

Robotics and Automation - Featured Company

Encoder Products Company

At Encoder Products Company, we specialize in the encoders that provide you with motion feedback. EPC has been a leading designer and manufacturer of motion sensing devices for more than 50 years, we understand that each industrial automation application is different, and you need encoders that fit the needs of your applications. Our encoders are highly configurable, offer an array of shaft or bore sizes, output types, connector types, mounting options, and resolutions as high as 65,536 CPR.