How to Handle Post-Holiday Returns with Warehouse Automation

The Warehouse Automation Industry Structure is Changing: Are You Ready for Disruption?

Implementing the Most Efficient Picking Paths to Meet Crucial KPIs

Dexterity AI and FedEx Unveil First-of-its-Kind Robotics Trailer Loading Technology

Tompkins Industries Reaches New Heights with its Vertical Lift Automation System

Motors In Automated Warehouse Operations

Goods-to-Person Picking Systems

Updating Warehouse Automation Solutions to Improve Productivity and Profitability

5 Compelling Benefits Of Automation In Your Warehouse

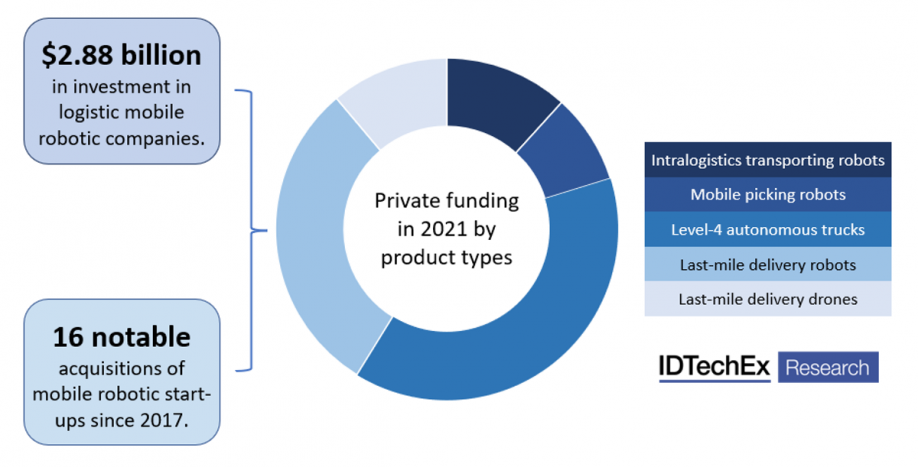

Innovation in Mobile Robots for Warehouse Automation

Maximising the Potential of AMRs with Software Integration

Random Depalletization

Accommodating Market Volumes and Staying Competitive with Scalable Sensor Solutions

Top of the Shops: Smart Warehouses & Evolving E-Commerce

How Does the "Goods-To-Person" Method Improve Warehouse Efficiency?

Records 16 to 30 of 81

First | Previous | Next | Last

Featured Product

Onward Robotics - Meet Me Fulfillment Automation

Robotics and Automation - Featured Company

.jpg)