The Hiring Freeze Came First. The Robots Came After.

This is not just a vibes-based assessment: in May, the U.S. reported around 332,000 open jobs in transportation, warehousing, and utilities, plus another 400,000 in manufacturing. Wages are up, benefits are better, yet demand still outpaces supply.

What is Agentic AI and is it here to stay?

Agentic AI is another concept that is slowly entering the vocabulary of professionals and the warehousing industry. How can it be used efficiently in the market, for what purposes, and what would be a potential timeline for adoption?

How LAPP Rebuilt Its Inventory Process with Autonomous Drones

For LAPP USA, Corvus One turned a labor-intensive, error-prone process into a nightly automated workflow that provides reliable visibility, reduces costs, and improves customer service.

How to Improve Warehouse Picking Speed with Automation

In warehousing, distribution, and e-commerce fulfillment centers, operational and customer success relies on fast and accurate fulfillment, but achieving and maintaining this service level can be challenging.

Order Picking Methods: Finding the Right Strategy for You

Order picking is widely reported to account for 50% to 55% of total warehouse operational costs. Identifying the right picking strategy can have a significant impact on the bottom line.

Upgrade Your Mezzanine Flooring While Avoiding Timely and Costly Replacement

Mezzanine floors are important in many facilities. They provide extra space for storage or work without taking up more ground space. However, they often face heavy use from equipment and people. Over time, this can cause the floor to wear down.

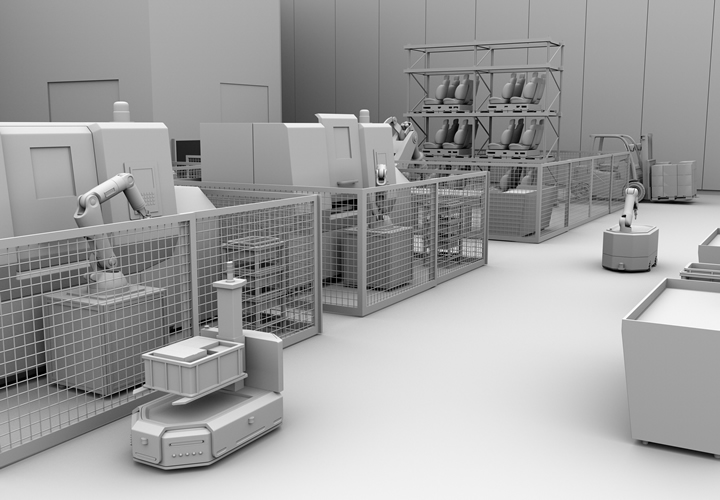

The Future of Manufacturing: Harmonizing Human Talent and Automation

The recent developments at Amazon's new robotic warehouse in Shreveport, Louisiana, offer valuable insights into this complex interplay between human workers and advanced technologies.

Revolutionizing Warehouse Floors: How AGVs & AMRs are Driving Safety in Modern Manufacturing

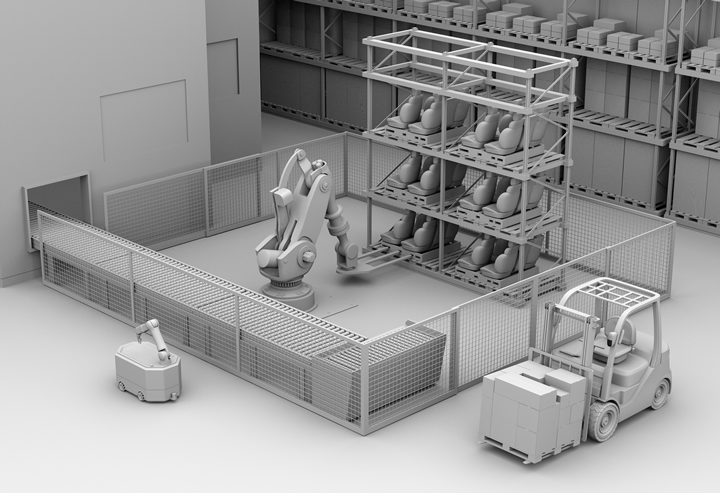

With automated systems, the possibilities for implementation are endless, but depending on your business goals and needs, automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) prove to be particularly impactful.

MHP study proves it: Wireless charging increases productivity of AGVs by 50%

The aim of the MHP study was to demonstrate the advantages of process-integrated charging points using inductive point charging systems such as Wiferion over conventional charging zones using a real-life optimization scenario in a medium-sized production company.

Automation isn't a one-size-fits-all: 5 key considerations for your warehouse

From AI-vision systems revolutionizing inventory management to advanced depalletization solutions streamlining logistics, we'll explore five critical considerations that can make or break your journey toward integrating robotics into warehouse operations.

Solving the logistics labor puzzle: Choreographing a Tango of Robots and Human Labor in Warehouse Operations

The most pressing dilemma for the logistics industry is perhaps maximizing output levels that match consumer needs while not having enough employees taking up physically demanding tasks like parcel picking and sorting.

Sneaker and Sportswear Retailer's New Mezzanine and Ground Floor Feature ResinDek Robotic Flooring

As directed by the facility's warehouse management software (WMS), a fleet of 142 AMRs continuously delivers mobile shelves to associates at workstations equipped with light directed picking modules on both floors.

The Interplay Between Robotics and Artificial Intelligence in Manufacturing

AI and robotics make the factories of the future smarter and more efficient. Manufacturers need to use these exponential technologies to gain a competitive advantage.

Are Labeling and Palletizing Robots the Secret Weapon Manufacturers Need?

Robots are not magic fixes to all manufacturing industry obstacles, but they can allow users to overcome many challenges when implemented thoughtfully.

What are the Key Camera Features of Warehouse Automation Drones?

Warehouse automation drones require advanced camera vision sensors and technologies to ensure performance. Enhancing the navigation accuracy and decision-making capabilities of drones can be achieved by incorporating appropriate camera features into their embedded systems.

Records 1 to 15 of 81

Featured Product

New incremental encoder IERF3 L from FAULHABER

FAULHABER is expanding its product range with the ultra-precise incremental encoder IERF3 L. Thanks to the optical measuring principle and state-of-the-art chip technology, the device offers the highest resolution, excellent repeatability, and outstanding signal quality. In typical applications, the positioning accuracy is 0.1° and the repeatability 0.007°. This makes the encoder the perfect solution for high-precision positioning applications in confined spaces.

Robotics and Automation - Featured Company

US Digital

US Digital's breadth of quality motion control products offers a range of sizes and CPRs, delivering the position accuracy you demand. With over 1 million off-the-shelf configurations, including custom designs and manufacturing, we put ultimate precision into your application. US Digital has delivered quality in motion since 1980. Located in Vancouver, WA, the vertically integrated facility and the stellar service team offer shorter lead times, with same-day fulfillment on most orders.