Building Customers' Trust With Robots - Advanced 3D Vision Systems Improve Food Traceability

Food traceability is not just a matter of compliance, it's also essential for maintaining customer trust and brand reputation.

3D Image Processing Solution With 2D Cameras, AI and Robotics Optimizes the Manufacturing Landscape

The easy-to-integrate system consists of a module for robot arms, a computing unit with pre-installed intelligent software and a camera module, each equipped in series with two uEye+ XCP cameras from IDS.

Automatic Loading and Unloading of Pressed Parts Through 3D Container Inspection

The actual workflow that FrameSense is designed to automate is part of many manufacturing operations. A component comes out of a machine - here a press - and runs on a conveyor belt to a container.

Stronger Outcomes for Automotive Component Machining with Enhanced Vision System

Reject rates limited to less than 5% of output with Matrox Design Assistant X-based vision inspection system

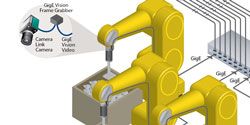

It's a Wrap Thanks to a Pick-and-Place Robotic Vision System

Prior to the upgrade the process involved manual removal and depositing of bread packages, which was potentially error prone and certainly not as efficient. The team at KINE knew that machine vision was the only possible solution for this type of system.

How Computers Deliver the Ability to See

Advances in semiconductors have led to dramatic developments in a wide range of sensor and camera technologies, including sensors/cameras for area scan and line scan, IP/network, 3D, and thermal imaging platforms.

Automate Image-based Inspection with Artificial Intelligence

A sentin VISION system uses AI-based recognition software and can be trained using a few sample images. Together with a GigE Vision CMOS industrial camera from IDS and an evaluation unit, it can be easily embedded in existing processes.

On the Track of Old Masters

The analytical examinations of the painting were carried out not only before starting the treatment, but also during the cleaning. This allowed valuable information to be gathered on the condition of the surface layers as well as the layer structure and the materials used.

Cut From the Same Cloth - Automatic 3D Recognition and Marking of Wooden Beams

An Ensenso N35 camera is used to capture the beam position and geometry. As soon as the timber is in the printing position, the robot automatically places the flange-mounted camera so that it can detect the surfaces of the beam.

Adaptive Robots

It combines high-performance force control, computer vision and advanced AI technologies, which enables the robot to adapt to the complicated environments, and accomplish better "hand-eye" coordination like human does.

Evolution of Embedded Vision Technologies for Robotics

The traditional vision architecture is changing, with an evolution from cameras and sensors to networked and smart-enabled, compact embedded devices with the processing power required for real-time analysis.

Records 1 to 11 of 11

Featured Product

Midwest Motion Products is a leading provider of robust and reliable Motion Control Products.

MMP specializes in supplying high-quality Brushed & Brushless DC Motors & Gearmotors for Robotics and Automation Equipment with a wide range of motor windings and gear ratios. With an impressive track record of more than 8,000 released DC Gearmotors designs and over 2,000,000 individual part numbers, we are renowned for our ability to handle large-scale orders. Due to our huge on-hand inventory, we are also well known for lightning-fast delivery of our standard products. We take pride in our dedicated customer service and our team of knowledgeable sales and engineering experts who are ready to assist you with custom design solutions tailored to your specific application. Additionally, we also offer a wide range of complimentary products, such as DC Motor Controls, DC Linear Actuators, AC-DC power Supplies, and DC Servo Amplifiers and others.

Robotics and Automation - Featured Company

MVTec LLC

MVTec is a leading international manufacturer of software for machine vision used in all demanding areas of imaging like the semi-conductor industry, inspection, optical quality control, metrology, medicine or surveillance. In particular, software by MVTec enables new automation solutions in settings of the Industrial Internet of Things. MVTec is the developer and vendor of the general purpose machine vision software products HALCON and MERLIC.