2021 Top Article - Sustainable Supply Chains in the Era of Industry 4.0

How Commercial Robotics Could Improve the Inventory and Shipping Crisis of 2021

5 MIR1000 Robots Automates the Internal Transportation of Heavy Loads at Florisa

Supplychainbrain: Out With Conveyors, in With Autonomous Mobile Robots

How AI is Changing the Future of Supply Chain Costs

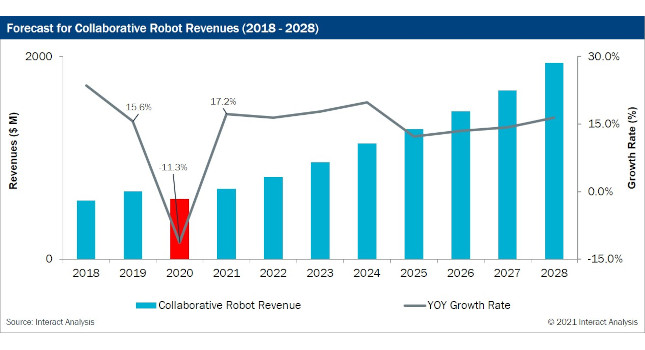

Drivers and Restraints to the Collaborative Robot Market

What OEMs Look for in the Perfect Robot Supplier

Without Micromotors Global Logistics Would Be Lost

Covid-19 - the accelerator to smart logistics, smart transportation and smart supply chain services

Thoughts on the Impact of COVID-19 and Essential Supply Chain Automation

The Internet of Robotic Things: How IoT and Robotics are Evolving to Benefit the Supply Chain

Covid-19 Impact on Food Automation and Robotics Market

Mobile Robots and Autonomous Vehicles: IDTechEx Analysts Discuss How Coronavirus Pushes Logistic Automation up the Agenda

The Importance of a Reliable Supply Chain for Robotics Companies

MODEX Q&A - Honeywell Intelligrated

Records 16 to 30 of 50

First | Previous | Next | Last

Featured Product

Onward Robotics - Meet Me Fulfillment Automation

Robotics and Automation - Featured Company