Talking AUTOMATE 2023 with TM Robotics

Talking AUTOMATE 2023 with Dorner

Automate 2023 Product Preview

Talking AUTOMATE 2023 with ATI

Tackling the lack of specialists with innovative robotics solutions

PACK EXPO 2022 Product Preview

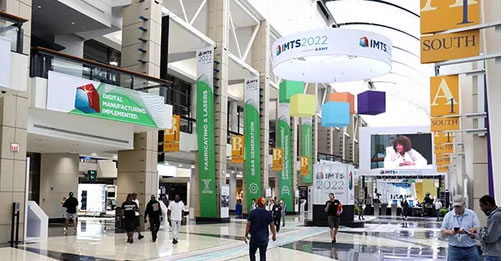

IMTS 2022 Opens Sept. 12, Showcases Digital Tech That Address Manufacturing's Biggest Challenges

What's in Store for the 2022 RoboBusiness Conference and the Field Robotics Engineering Forum?

IMTS 2022 Product Preview

ATI Industrial Automation at IMTS 2022

HEIDENHAIN at IMTS 2022

Early bird registration for RoboBusiness ends August 20, 2022

Automate 2022 Product Preview

ATX West and IME West 2022 Product Preview

How-To Guide on Mastering PACK EXPO Connects

Records 16 to 30 of 286

First | Previous | Next | Last

Featured Product

Elmo Motion Control - The Platinum Line, a new era in servo control

Robotics and Automation - Featured Company