Stefa Mini Solutions for Next-Generation Robotic Applications

The Stefa Mini, Cassette and Nano Seals all have smaller cross sections than comparable seals in the market today. This matters because a smaller seal allows for smaller glands (the area the seal slips into on the equipment) and smaller glands mean overall smaller equipment.

How to Build a Digital Foundation for Your Robotics and Automation Strategy

A strong digital foundation brings everything together, allowing automation initiatives to scale, adapt and perform as intended. Without it, automation efforts often stall before they reach their full potential.

Powering Robotics: How Networks Enable the Era of "Physical LLMs"

Physical AI describes intelligent systems that can sense, interpret, and act in real environments. Think of self-driving cars navigating busy streets, robotic arms assembling machinery with precision, or smart grids adapting in real time to energy demands.

The ifm Obstacle Detection System (ODS)

The ifm Obstacle Detection System (ODS) optimizes the robot's overall performance by treating obstacle detection as a holistic system rather than just a camera. It provides reliable obstacle detection to protect people, equipment, and mobile robots.

Robot-Driven Manufacturing Enables "Lights-Out" Production

The required solution would need to provide seamless connectivity and communication with the RoboDrill machines, as well as additional factory machinery throughout the company targeted for robotic automation moving forward.

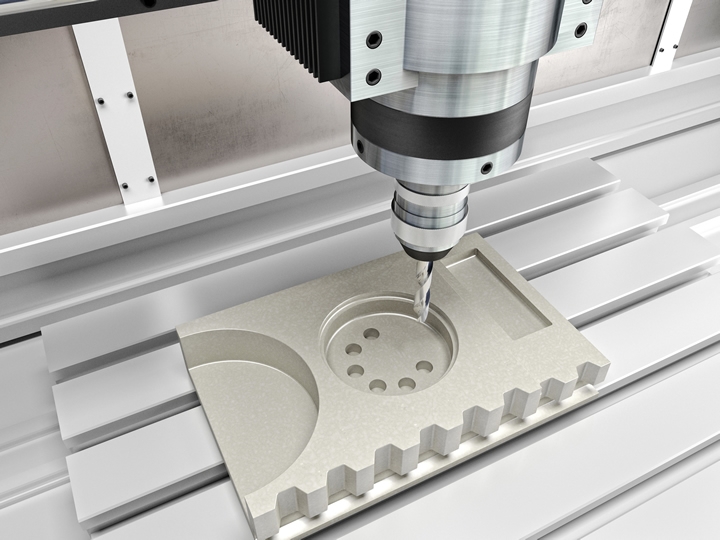

Robotecki Redefines Robotics Precision Cutting and Drilling Applications with RoboDK

With their application, the team at Robotecki not only reduced labor-dependency for these key tasks, they improved the quality of production and throughput.

The Role of Emotional Intelligence When Implementing Industrial Robotics

Emotional intelligence remains a vital leadership skill for manufacturing and industrial leaders embracing robotics. Here's why it matters and how leaders can foster it, helping organizations reap the full benefits of automation while maintaining human-centric workplaces.

2025 Top Article - Redefining industries with robotics and AI

While robotics have been a staple in the automotive manufacturing industry for decades, the applications have now spread far beyond, reshaping industries from agriculture to healthcare and service industries.

2025 Top Article - The Future of Machining: Key Trends and Innovations

AI and robotics are seen to deeply disturb specialized industry sectors, bringing beneficial pioneering modernizations in machining, industrial manufacturing and machine shops. Elitsa Krumova explores the future of machining in more depth on behalf of DELMIA.

StackTrax - The Industry's First Off-The-Shelf Dual Axis RTU

Compared to alternative solutions, such as multiple robots or overhead gantry systems, StackTrax can provide a space and cost-saving alternative that will improve cycle time and overall throughput.

CASE STUDY STT SYSTEMS and STEMMER IMAGING: AUTOMOTIVE BOLT INSPECTION SYSTEM WITH GOCATOR SMART 3D LASER PROFILERS

LMI Technologies, in partnership with STT Systems and Stemmer Imaging, implemented an automated quality inspection system to detect missing bolts on automotive blanks. The system integrated multiple Gocator 3D sensors and an RFID tracking system for real-time analysis.

How U.S. Manufacturing VPs Can Close the Execution Gap — The New Playbook for Operational Excellence

Operational excellence used to mean efficiency. Now, it means consistency.

In a volatile manufacturing environment, the winners aren't those with the best machines or biggest budgets — they're the ones who can execute the same playbook flawlessly, every day, on every line.

BTM INDUSTRIAL IS HOSTING AN ONLINE SALE OF INDUSTRIAL ROBOTS ON DECEMBER 17-18, 2025

Includes more than 200 robots designed to automate tasks, such as welding, manufacturing, packaging, warehousing, and food processing. This court-authorized sale requires the liquidation of all assets, regardless of price.

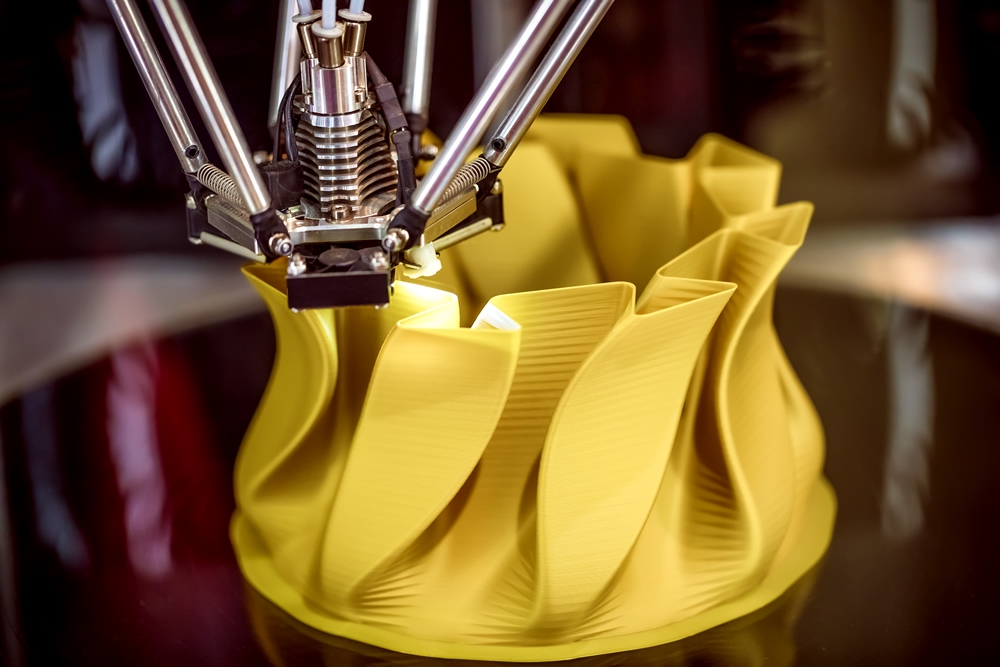

What are the motion control requirements for additive manufacturing machines?

3D printed objects can include intricate machine components, through to edible items, and as a result, the additive material could range from powdered metals to chocolate. Whatever the material and shape required, functionally, the 3D printing technique is the same.

SoftBank's $5.4B ABB Robotics Deal: Why IT Service Providers Should Treat Robotics as a Core Practice

As autonomy and embodied intelligence mature, IT service providers may not need to participate in every layer, but those who develop focused capabilities—whether in advisory, integration, or managed operations—will be better placed as demand grows.

Records 1 to 15 of 1299

Factory Automation - Featured Product

Oriental Motor USA - Ideal for AGV/AMR Applications

The BLV Series R Type brushless DC motor (BLDC motor) speed control system offers the design of motor and driver significantly reduced in size and weight, yet high-power, and contributes to the battery driven automation. The BLV Series R Type is compatible with the two interfaces of Modbus (RTU) and CANopen communication.

Robotics and Automation - Featured Company

Encoder Products Company

At Encoder Products Company, we specialize in the encoders that provide you with motion feedback. EPC has been a leading designer and manufacturer of motion sensing devices for more than 50 years, we understand that each industrial automation application is different, and you need encoders that fit the needs of your applications. Our encoders are highly configurable, offer an array of shaft or bore sizes, output types, connector types, mounting options, and resolutions as high as 65,536 CPR.