AI-Driven Grasp Depth Estimation

The core innovation of our new patent lies in its self-supervised approach to depth estimation. What that means is, the AI learns to judge the depth of an item it needs to pick up by using its own sensor data and the feedback it gets from its actions.

Automate 2025 Q&A with Zimmer Group

We have evolved from a manufacturer of single components to becoming a full-range provider of complex system solutions in the field of robotics. Our portfolio covers the entire automation spectrum - from high-functioning grippers to robot accessories.

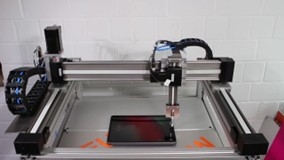

Low-Cost Robotics Elevate Industrial Inspection Processes

Learn how to easily and cost-effectively design and procure turnkey automation systems using a robotics platform, taking inspection tasks to the next level.

Automating pick-and-place in food manufacturing

The requirements included automatic pick and place of up to 60 keys per minute, seamless integration with the existing production line and a minimal factory floor footprint.

DESTACO Smart Electric Product Line of Clamps and Guides

The new smart electric product line represents a substantial leap forward in the automation and industrial clamping landscape, offering enhanced precision, energy savings, and seamless integration for modern manufacturing processes.

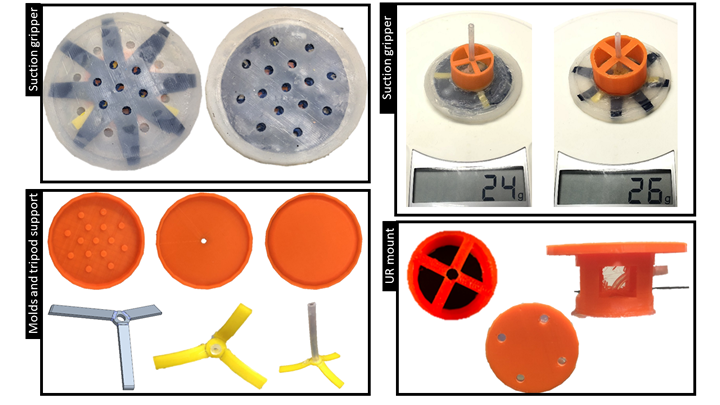

Harvestance - Developing and Designing Vacuum Grippers for Production Line Robots

Harvestance has received numerous inquiries for the design and manufacture of customized, lightweight, and strong grippers for collaborative robots, aimed at automating production lines.

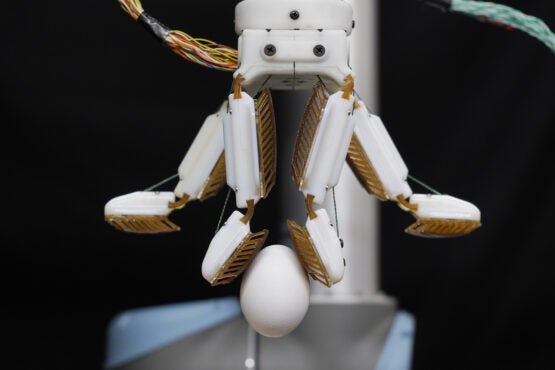

4 Ways Soft Gripper Robots Improve Food Processing

Food processors often deal with challenges when delicate items are mishandled and broken or dropped. Soft gripper robots can tackle this problem, especially since many are specially designed to handle fragile items, such as eggs.

This 3D Printed Gripper Doesn't Need Electronics To Function

This soft robotic gripper is not only 3D printed in one print, it also doesn't need any electronics to work. The device was developed by a team of roboticists at the University of California San Diego.

Sheet-Jamming Technology Revolutionizes Soft Robotics Grippers

To improve the performance of suction grippers, a new concept called sheet-jamming phenomena has been introduced. This technology has been used to create a suction gripper that is lightweight and can lift almost twice the weight of regular suction cups.

End-of-Arm-Tooling powered by Stäubli Fluid Connectors

Stäubli Fluid Connectors presents a new End-of-Arm-Tooling range: The mechatronics specialist offers a broad technology portfolio from a single source coupled with advice for individual solutions in robotic material handling.

Automatic box palletizing in the food industry

BX suction cups made of double-strength Duraflex® in combination with Piab's COAX® vacuum generation technology have enabled Tradicional Panadera to palletize different carton formats with a single gripper.

Everything Under Control

In modern systems, "pick-and-place" is performed by automated grippers. They must be able to operate both powerfully and delicately and do so precisely and reliably millions of times over. Increasingly, the necessary power comes from electric motors.

Soft Grippers Can Handle Small and Delicate Parts With Greater Ease

This opens up new possibilities in robotic automation and even some cutting edge robotics applications. From injection molding to strawberries and even robotic surgeries, soft gripper technology is making it easier than ever before for robots to pick up anything.

Stanford engineers develop a robotic hand with a gecko-inspired grip

Aiming to create a robotic gripper that can grasp with delicate strength, researchers combine adhesives based on gecko toes with a customized robotic hand.

4 Amazing Advancements in Robotic Grippers to Keep an Eye On

As manufacturing sectors of all kinds struggle with a growing labor gap, these collaborative grip designs can help streamline facility workflows, reducing the labor necessary to complete tasks while keeping the facility flexible and adaptable.

Records 1 to 15 of 65

Featured Product

Strain Wave Gearheads by maxon - Highly precise, compact, and efficient.

Strain wave gearheads are ideal for use in applications requiring precision motion control and high torque transmission in a compact design. maxon strain wave gearheads are a specialized type of gearhead where precision and compact design are crucial. This type of gearhead is often used in applications in a confined space. With their advanced gear tooth design, maxon's strain wave gearheads provide high efficiency and good back drivability. Typical applications include: Robotics, Aerospace, Medical technology and Optical systems .

Robotics and Automation - Featured Company

FAULHABER MICROMO

Since 1961, FAULHABER MICROMO has partnered with OEMs to deliver high precision, high performance, custom micro motion system solutions to markets such as medical, robotics and automation in North America. FAULHABER MICROMO's tradition of innovation started decades ago in Germany. The groundbreaking invention of the FAULHABER coreless winding started it all for a market that produces millions of motors today.

How can the FAULHABER MICROMO team help you deliver your next innovation to market first?

Learn more about MICROMO's solutions for the most demanding applications, our diverse motion products and technologies, online ordering, Engineering and R&D teams, Clean Room Assembly, Machining Center and other services at our Clearwater, FL facility at https://www.faulhaber.com.

.jpg)

.jpg)