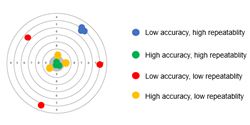

What are Resolution, Accuracy & Repeatability

Understanding resolution, accuracy and repeatability is critical to specifying a position sensor. This paper defines these terms and discusses how they relate to overall system performance.

How to Choose the Right Sensor in Ambient Conditions

One of the key considerations while choosing the perfect set of sensors for your robotic designs include their resistance to ambient situations such as temperature, lights, interferences and obstructions.

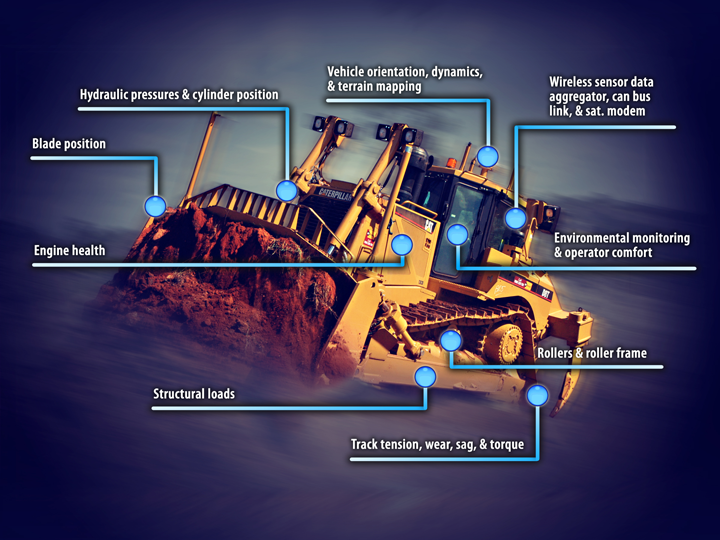

High Performance Inertial Sensors for Robotic Systems

The next generation of robotic systems require high performance inertial sensors but also demand high volume, low cost solutions.

How to Improve Worker Safety Around Robotics

Industrial robots offer increasingly compelling opportunities to help companies get more done and promote consistency in the workplace. Robot safety is another area of concern, especially since robots can reduce some of the risks that cause accidents.

Choosing the Right Inertial Sensor for your Robot

The latest generation inclinometers provide much more stable performance and higher accuracy.

Robot Sensor Market Outlook

The Robot Sensors Market has developed rapidly and boasts of an extensive product base, with estimated earnings of over USD 2 billion in 2017.

The use of Inertial Sensors in Robotics

The primary uses for inertial sensors are platform stability and global positioning, but we are seeing increasing use as feedback in articulated limbs.

7 Reasons Your Life Depends on an Accurate IMU (Inertial Measurement Unit) in a Self-Driving Car

An inertial measurement unit (IMU) is a device that directly measures the three linear acceleration components and the three rotational rate components (6-DOF) of a vehicle.

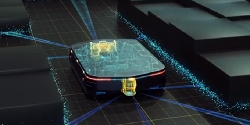

How Industrial Self-driving Vehicles Use Sensors for Localization and Mapping

OTTO self-driving vehicles depend on three different sensors to identify its current position as well as to navigate where and how it needs to travel from point A to point B. As in any dense and dynamic environment, elements in OTTOs path can change minute to minute

Industrial Robots: Encoders for Tool Center Point Accuracy

The use of secondary encoders on all of a robots axes, as well as the use of linear encoders for positioning the robot relative to the workpiece, enables a level of accuracy at the tool center point

Interview with Shaoshan Liu and Zhe Zhang of PerceptIn

Using our technology, we are able to reduce the cost of the whole vehicle (including the chassis, the computing hardware, and the sensing hardware, and the software stack) under $10,000 USD.

Q&A with Hillcrest Labs - High Value AHRS/IMUs Enable Low Cost Robot Navigation

The module allows rapid development of new robots by providing all the sensors and sensor processing software in one compact, pre-calibrated device with multiple interfaces supported to meet varying developer requirements.

Soft Stretchy Sensors

When the sensor is integrated into a wearable device and placed across a joint, it is stretched when the joint moves. We can correlate the joint's movement and sensor's capacitance change in order to monitor motion.

Sensors Expo & Conference Partners with Xconomy for Robo Madness West co-location

5th annual event to feature brightest minds and hottest technologies in the world of robotics

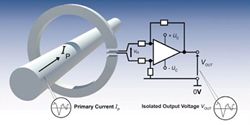

New Open Loop Current Transducers With Near Closed Loop Performance

Measured performance is at the level expected and increases the range of applications which may be addressed by open loop transducers instead of more complex solutions.

Records 1 to 15 of 39

Featured Product

Palladyne IQ - Unlocking new frontiers for robotic performance.

Palladyne IQ is a closed-loop autonomy software that uses artificial intelligence (AI) and machine learning (ML) technologies to provide human-like reasoning capabilities for industrial robots and collaborative robots (cobots). By enabling robots to perceive variations or changes in the real-world environment and adapt to them dynamically, Palladyne IQ helps make robots smarter today and ready to handle jobs that have historically been too complex to automate.

Robotics and Automation - Featured Company

PDS / Precision Drive Systems

Over 40,000 Spindles Repaired or Rebuilt Since 1996. PDS is a global leader in spindle repairs and retrofits for precision metal and robotics applications. With over 40,000 spindles repaired to better than-new-condition. PDS also offers new spindles, CNC accessories, and Industry 4.0 spindle monitoring. With offices in Bessemer City, NC (near Charlotte) and Herford, Germany PDS backs superb craftsmanship with a standard 12 month warranty on repaired spindles and an optional, industry-leading 24 month PrecisionCare warranty.

.jpg)