Micropsi Industries' moves HQ from Berlin to the U.S.

Stretch and Spot: Increasing Operational Efficiency and Making Warehouse Work Safer

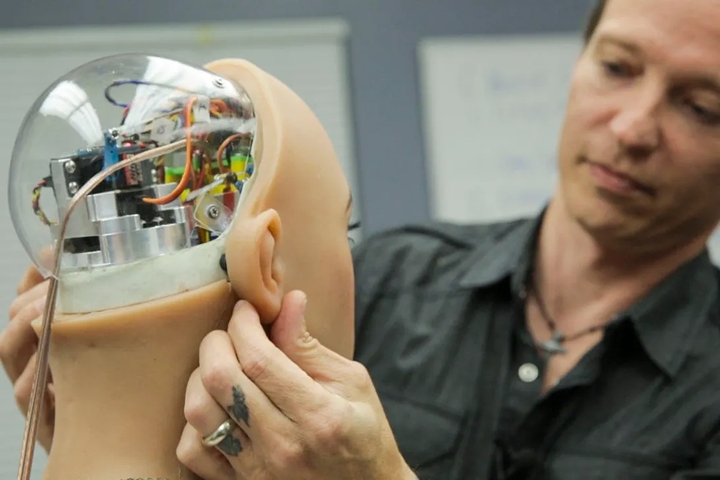

AI Capabilities in Humanoid Robots

Making Pittsburgh a Leading Hub for Robotics and AI

AI & Autonomous Solutions in Agriculture

The Robot Driven Logistics Industry

DESTACO Smart Electric Product Line of Clamps and Guides

Embracing a Purpose Built AIML System in Robotics

Top Viewed Articles of 2023

Trends in Industrial Robotics to Watch in 2024

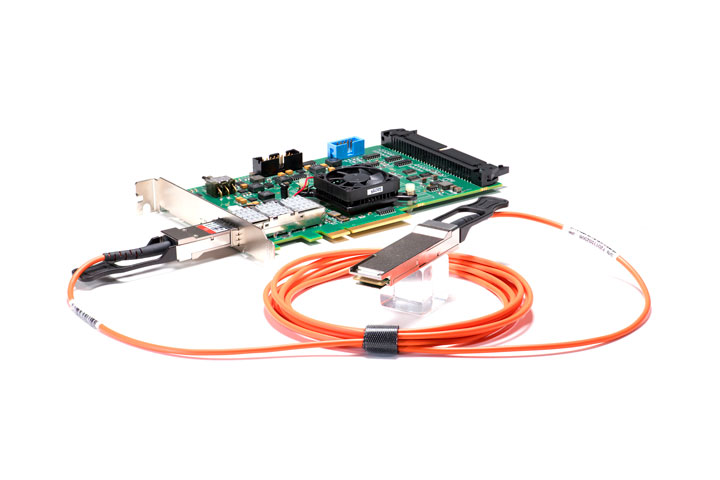

CoaXPress over Fiber

Important Trends Impacting the AMR Space

Bringing Robotics to Small Manufacturing

Utilizing AI in the Manufacturing Space

Talking PACK Expo with Brenton Engineering

Records 31 to 45 of 184

First | Previous | Next | Last

Featured Product

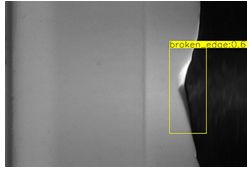

CMES - AI-Powered 3D Robot Vision

Robotics and Automation - Featured Company