Meet the Robots Taking Over a Tokyo Airport for the 2020 Olympics

University of Virginia Maps Historic Tunnel Using Jackal UGV

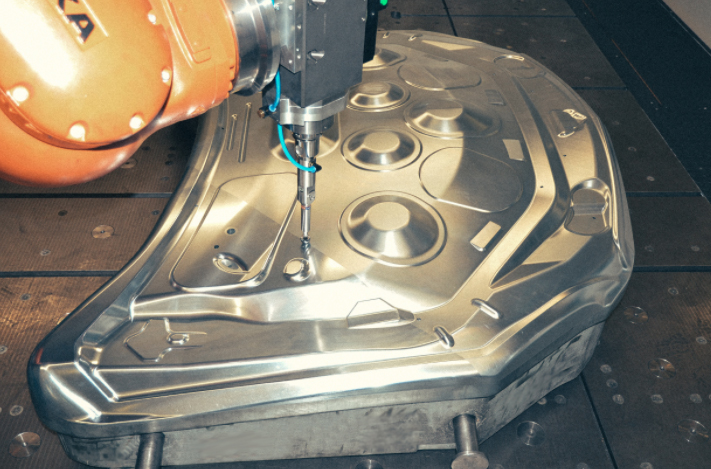

Offline Programming Software is Single Solution for Robotic Hammer Peening of Automotive Stamping Dies

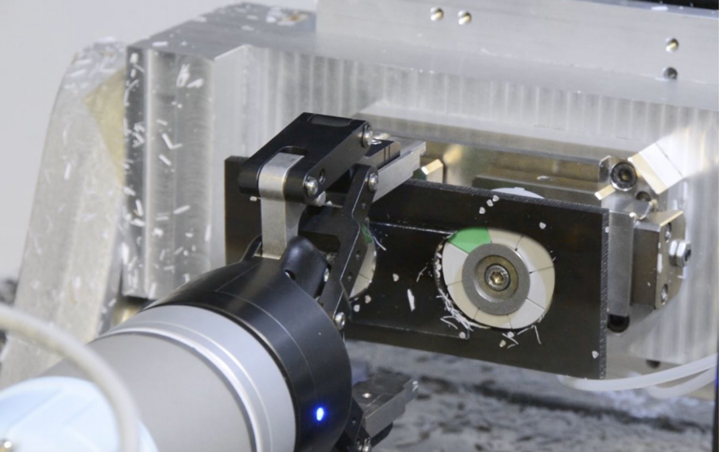

Reduce"‹ "‹Injuries"‹ "‹and"‹ "‹Increase"‹ "‹Productivity"‹ "‹with"‹ "‹the FT"‹ "‹300"‹ "‹Force"‹ "‹Torque"‹ "‹Sensor

Case Study: ATI Tool Changers Transform Schmalz's Design-Test Center

Wrist"‹ "‹Camera"‹ "‹Increases"‹ "‹Daily"‹ "‹Production"‹ "‹to"‹ "‹Deliver Big"‹ "‹Orders"‹ "‹in"‹ "‹Tight"‹ "‹Delays

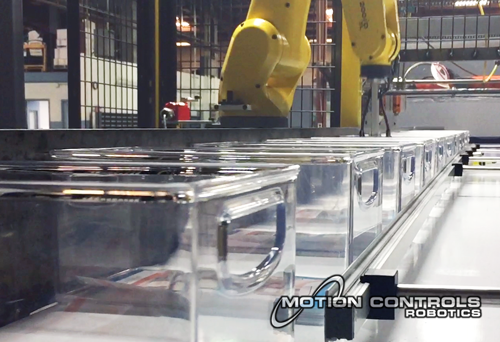

Robotic Label Placement

Case Study: Flex uses mobility to stay lean

Farason Corporation Chooses Dorner Conveyors to Integrate with its Robotic Machine to Successfully Assemble Coin Proof Sets

Building Up Today's Manufacturing Startups: Lowercase NYC

How Dynamic Group Quadrupled Production Capacity with Collaborative Robots

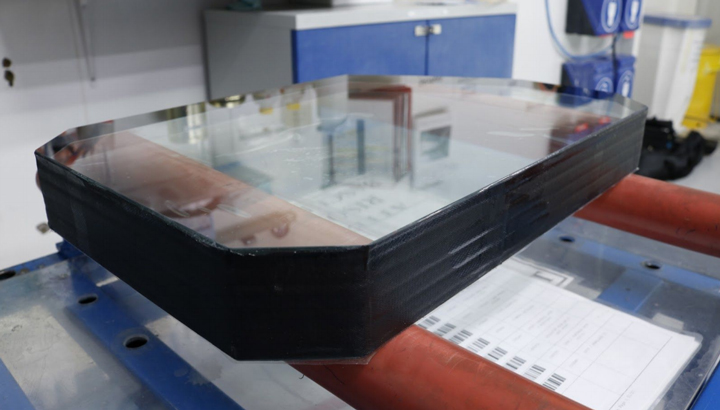

Robotmaster Reduces Outsourcing, Increases Production and Profitability

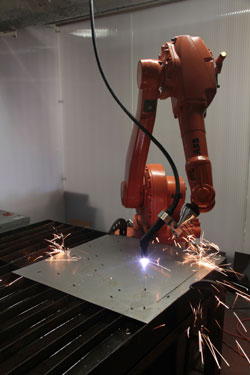

Carnegie Mellon Successfully Exploiting Manufacturing Robots

RR Floody's Powerful New Flexible Feeder System Pairs Mitsubishi Electric Robot and Cognex Vision System

Tru-Trac Keeps Frankenstein Alive

Records 31 to 45 of 55

First | Previous | Next | Last

Featured Product

Strain Wave Gearheads by maxon - Highly precise, compact, and efficient.

Robotics and Automation - Featured Company

.jpg)