COMPUTER VISION AND ROBOTICS EXPAND INDUSTRIAL CAPABILITIES

Machine Automation Taken to the Next Level

FT-Produktion Boosts Output Capacity Without Adding Personnel by Employing Combination of Collaborative Robots and Robot Grippers

With Piab's Bag Grippers, Sapho Increases Its Pace

World's First Composite Concrete 7th Axis used for the First Time In Series Production at Car Manufacturer

Concept Systems and ATI Deburring Tools Reshape Aluminum Manufacturing Processes

Güdel Integrates Tool Changers in Multi-Purpose Metal Forming Solution

ATI's Connections Help Map the Galaxy with "WEAVE"

NIDEC GPM Strengthens Innovative Capacity Thanks to Mobile Robots

Furniture Assembly - with Ensenso N35

Universal Robots Solves Production Challenges in Creating Revolutions' Assembly Line

Argon Medical Addresses High Labor Costs and Productivity with MiR Robot

Case Study: Epson Robots at Taylor Guitars

PRE-TEC Integrates ATI Tool Changers in a Fast Finishing Solution

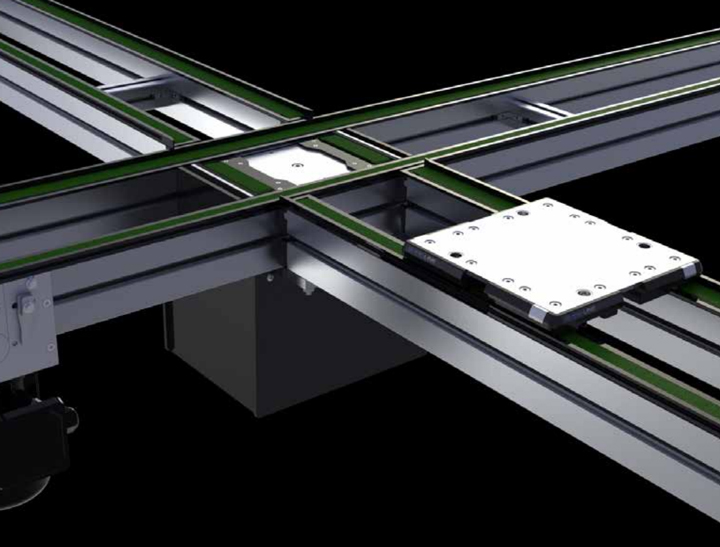

Glide-Line Conveyor Case Study: Automating in-context Conveyor Configuration With Solidworks

Records 16 to 30 of 55

First | Previous | Next | Last

Featured Product

3MP HDR IP69K Camera for Robotics & Autonomous Vehicles

Robotics and Automation - Featured Company