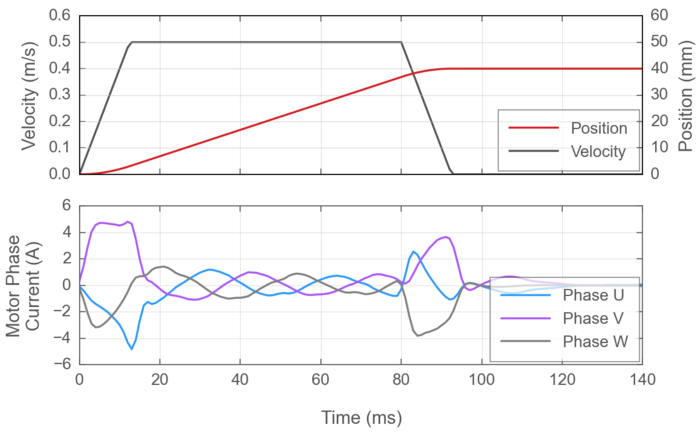

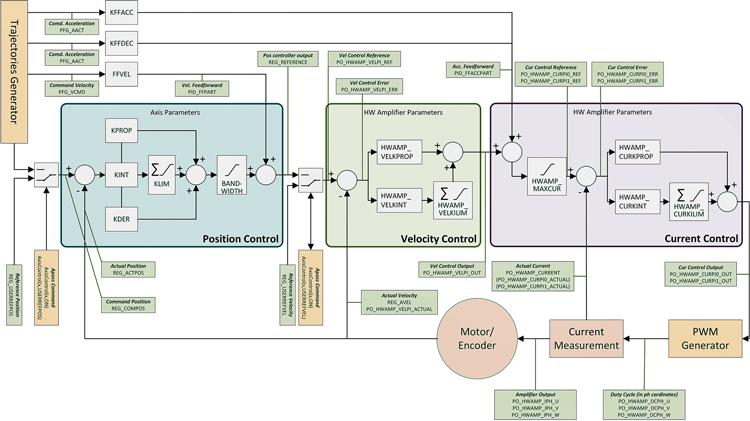

Enabling Peak Servo Performance with Thermal Protection

Q&A with Cortona3D

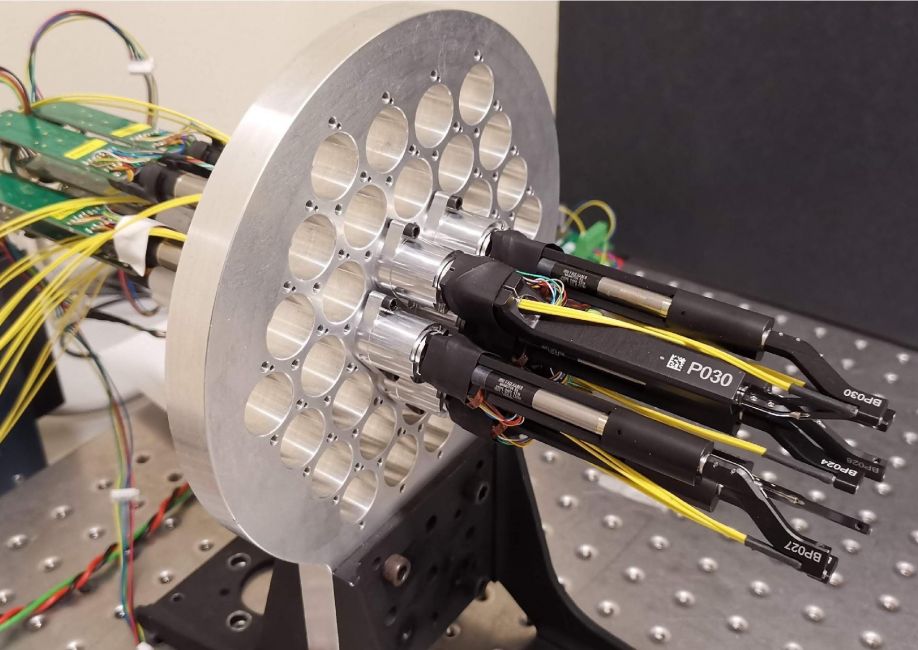

Mapping the Stars, Galaxies and Black Holes in the Universe, Thanks to Precision of Faulhaber Motors & Systems

MiniMACS6 Stabilizes the Furuta Pendulum

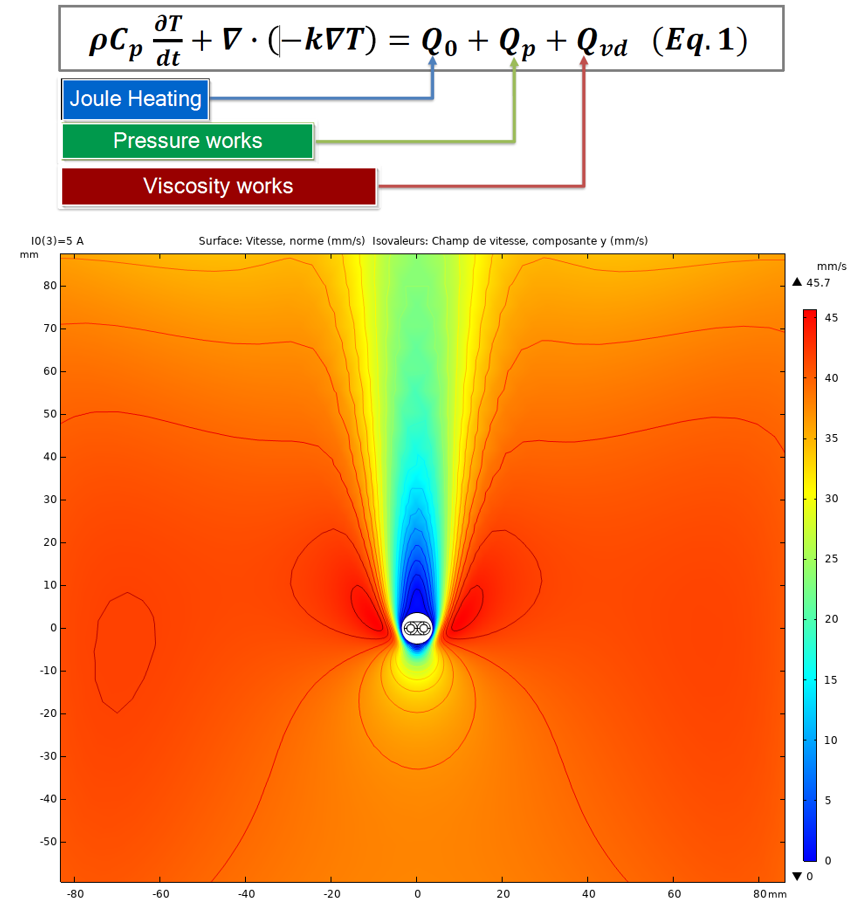

Simulating Heat Transfer in Power Cables Using the Finite Element Method (FEM)

2021 Top Article - How to Find the Right Damper for Your Application

True Flexibility in your Robotics System

Evolution in the Press Shop - Intelligent, Camera-based Tool Protection in Stamping and Forming Technology

How to Select the Best Motor for a Jointed Arm Robot

Choosing the Right Encoder for Your Robot

Handling Omnidirectional 3D Vision Data in Mobile Robots

How to Select the Right Motor for Your Robot

Benefits of a Tactical Grade IMU in Low-cost GNSS/INS Systems

6 Cool Servo Drive Features You Might Not Know About

How Robotics is Transforming Manufacturing

Records 16 to 30 of 66

First | Previous | Next | Last

Featured Product

Midwest Motion Products is a leading provider of robust and reliable Motion Control Products.

Robotics and Automation - Featured Company